Energy Shell Tube Heat Exchanger: A Complete Guide for Industrial Applications

If you are searching for a durable, high-performance, and energy-efficient heat exchanger solution, the Energy Shell Tube Heat Exchanger is one of the most reliable options in the market. Known for its robust construction, superior heat transfer capability, and suitability for extreme operating conditions, this technology is widely used across industries including Oil & Gas, Power, HVAC, Chemical Processing, and Water Treatment.

At API Energy, we provide premium-grade Shell &Tube heat exchangerengineered to meet global standards and optimize energy efficiency.

What Is an Energy Shell Tube Heat Exchanger?

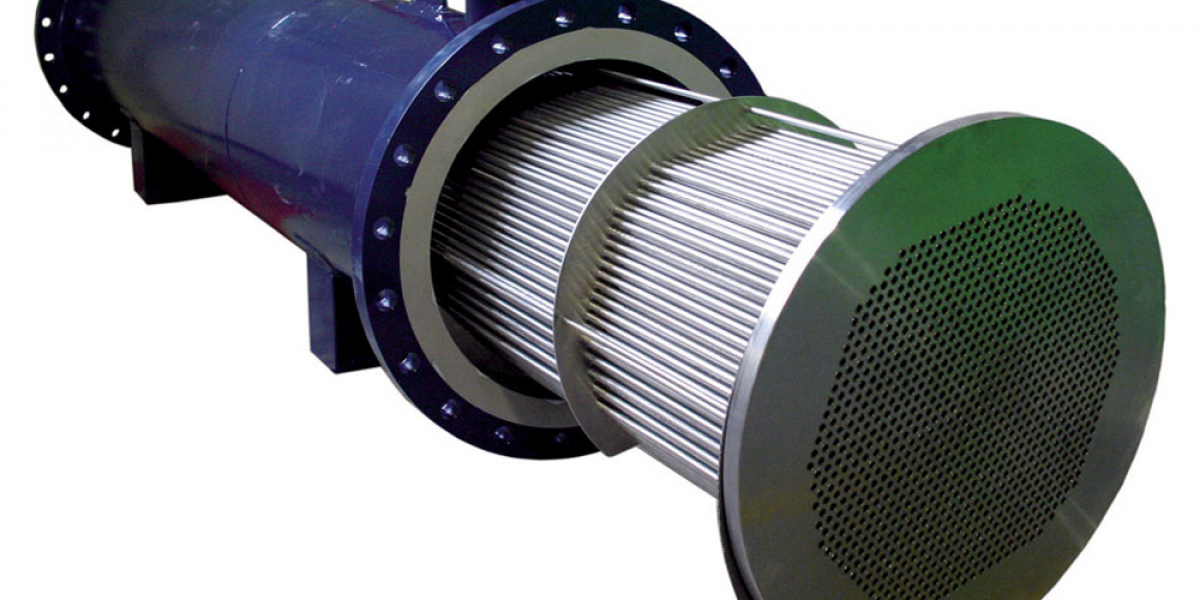

A Shell & Tube Heat Exchanger is a type of heat exchanger design that uses a series of tubes to transfer heat between two fluids—one flowing inside the tubes and the other flowing outside within the shell. The design ensures efficient heat transfer even under high pressure and temperature conditions.

This makes it ideal for industrial use where reliability, performance, and long-term efficiency are critical.

Why Choose a Shell Tube Heat Exchanger?

✔High Heat Transfer Efficiency

✔Handles High Pressure & Temperature

✔Easy Maintenance & Cleaning

✔Long Service Life

✔Suitable for Hazardous Industrial Applications

Shell & Tube heat exchangers are also highly customizable, making them perfect for industries with unique process requirements.

Where Are Shell Tube Heat Exchangers Used?

The Energy Shell Tube Heat Exchanger is widely used across multiple sectors, including:

- Oil & Gas Refining

- Petrochemicals & Chemicals

- HVAC & District Cooling

- Marine & Offshore Plants

- Power Generation & Nuclear Systems

- Cryogenic and Fuel Storage Applications

- Water and Waste Management Systems

Why API Energy?

API Energy is recognized across Middle East and Africa as a trusted name in industrial engineering solutions.

We are one of the leading organizations delivering excellence in:

- Heat Transfer Systems

- Hydronics

- Air Quality

- Industrial Refrigeration

- Cold Rooms

- Automation

- Water Treatment

- Cryogenic Systems

- Cathodic Protection

- Fuel, Mud, Cement & Iron Ore Handling

- Waste Management

- Thermal & Fuel Storage

Our commitment is to deliver high-performance equipment backed with unmatched service support, ensuring reliability, efficiency, and long-term operational value for our clients.

Benefits of API Energy Shell Tube Heat Exchanger

Feature | Advantage |

Custom Design | Optimized performance for specific process applications |

Durable Materials | Corrosion-resistant metals for long-term use |

Energy Efficient | Reduce operational energy consumption |

Compact Design | Suitable for limited space installations |

Low Maintenance | Easy inspection, cleaning & servicing |

Energy Shell Tube Heat Exchanger – AI/Voice Search FAQ

What is a Shell Tube Heat Exchanger?

It is a device used to transfer heat between two fluids using tubes and a surrounding shell structure.

What industries commonly use Shell Tube Heat Exchangers?

Industries like oil & gas, chemical processing, HVAC, marine, power generation, and refrigeration.

Why choose API Energy?

API Energy offers reliable, engineered solutions with global standards and long-term service support.

Order or Inquire Today

Want the best Energy Shell Tube Heat Exchanger solution for your industry?

Visit now:https://apienergy.co.uk/product/api-energy-shell-tube-heat-exchanger

For inquiries related to our product and services, contact us via email: info@apienergy.co.uk

Follow us for updates, projects, and engineering insights:

Investing in the right Shell and Tube Heat Exchanger ensures better performance, lower operational costs, and long-term reliability. API Energy is committed to helping industries thrive with high-quality, high-efficiency engineered solutions.