In the pharmaceutical industry, patient safety and drug quality are the highest priorities. Pre-filled syringes (PFS) have gained significant popularity in recent years due to their convenience, accuracy, and ability to reduce dosing errors. However, ensuring the sterility, integrity, and safety of these syringes remains a critical challenge. To address this need, advanced Pre-filled Syringe Inspection Machines have become an essential part of modern pharmaceutical production lines.

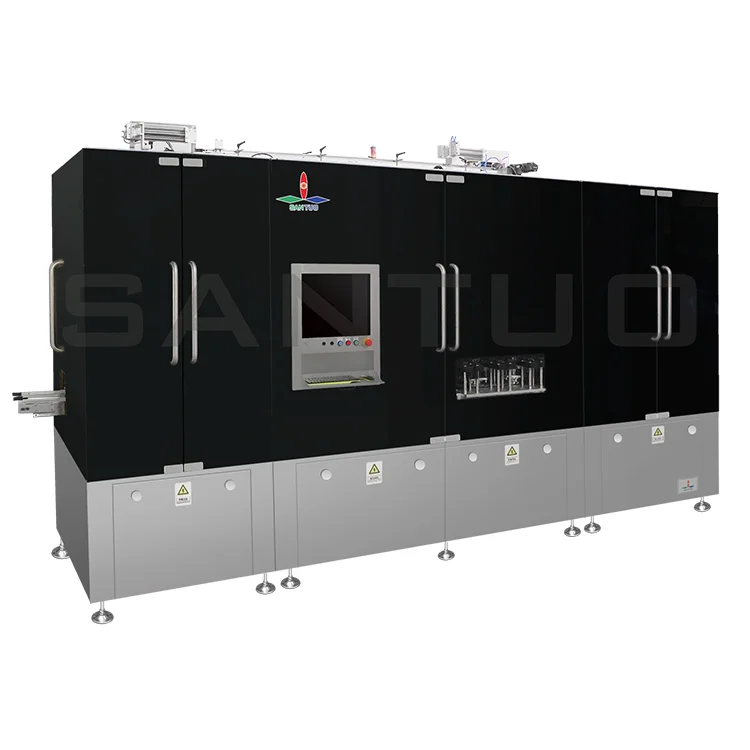

Among the leading solutions in this field, the Pre-filled Syringe Inspection Machine by SANTUO stands out. With its intelligent closed-loop process of “de-nesting → inspection → re-nesting”, it provides comprehensive protection for drug quality and patient safety.

Why Inspection of Pre-Filled Syringes Is Critical

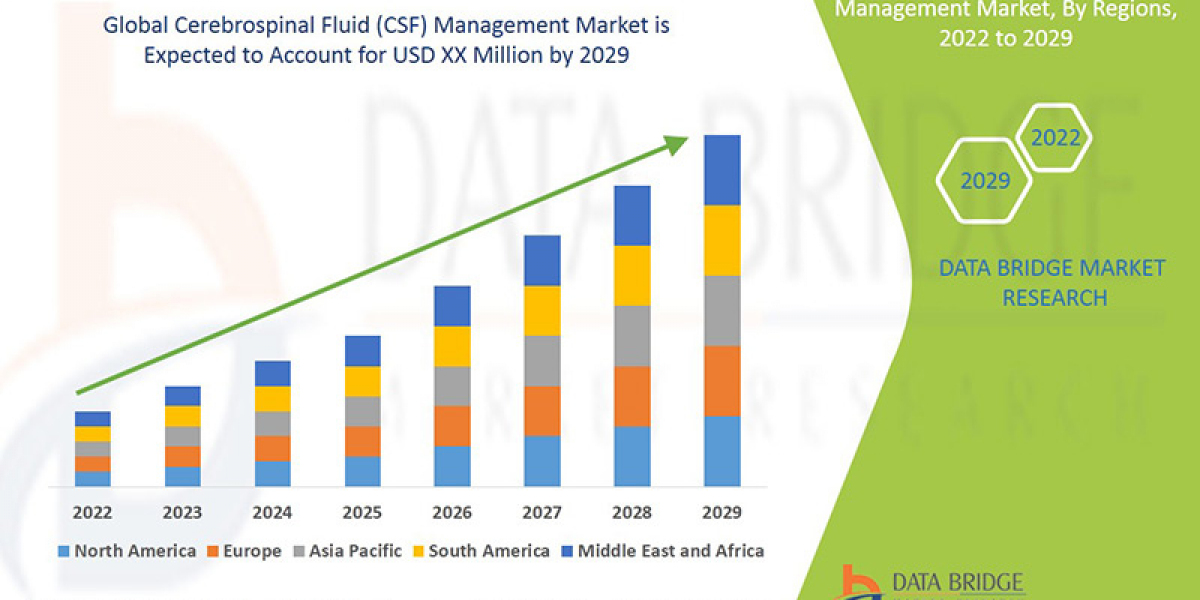

1. Growing Demand for Pre-Filled Syringes

With the rise of injectable biologics, vaccines, and chronic disease treatments, the demand for pre-filled syringes has surged globally. Their user-friendly design allows patients and healthcare professionals to administer medications quickly and safely.

2. Risks Without Proper Inspection

Despite their advantages, pre-filled syringes are prone to quality risks such as:

Foreign matter contamination (dust, fibers, particles).

Air bubbles mistaken for contaminants.

Cosmetic and structural defects (cracks, scratches, skewed needles).

Packaging failures (damaged caps, improper seals).

Without reliable inspection, these defects can compromise sterility and patient safety, leading to recalls and reputational damage.

The Intelligent Closed-Loop of SANTUO’s Pre-Filled Syringe Inspection Machine

SANTUO has designed a next-generation Pre-filled Syringe Inspection Machine that creates an intelligent closed-loop system covering every stage of inspection:

De-nesting – Syringes are automatically removed from trays with precision handling, avoiding physical damage during transfer.

Inspection – Advanced optical and AI-driven algorithms examine each syringe for foreign matter, bubbles, cracks, scratches, and other defects.

Re-nesting – After inspection, qualified syringes are safely placed back into trays, maintaining sterility and order for downstream processes.

This closed-loop system ensures efficiency, accuracy, and contamination-free inspection.

All-Dimensional Visible Foreign Matter Detection

One of the biggest challenges in syringe inspection is differentiating between natural drug characteristics and true contaminants.

Proprietary Bubble-Elimination Algorithm: SANTUO’s unique algorithm effectively distinguishes harmless bubbles from harmful particles. This reduces false alarms, streamlines production, and improves overall reliability.

360° Detection: High-speed cameras capture every angle of the syringe, identifying even the smallest particles that could pose safety risks.

The result is a significant improvement in detection accuracy without unnecessary product waste.

Precise Capture of Appearance Defects

Packaging defects can pose just as much risk as foreign matter. A skewed needle or a damaged cap can compromise the sterility of the syringe, leading to microbial contamination.

SANTUO’s Pre-filled Syringe Inspection Machine ensures:

Needle Alignment Verification: Prevents bent or misaligned needles that could hinder safe injection.

Cap Damage Detection: Identifies cracks, chips, or improper sealing that could compromise sterility.

Body Inspection: Detects scratches, stains, or cracks on syringe barrels that might affect drug safety.

By catching these defects in real time, the system eliminates risks before syringes reach patients.

AI and High-Speed Camera Technology

SANTUO combines AI-powered algorithms with high-speed cameras for precise and efficient inspection:

Real-Time Imaging: High-resolution cameras capture syringe surfaces at multiple angles, instantly detecting abnormalities.

AI Classification: Machine learning models analyze defects, categorize them, and make accurate pass/fail decisions.

Automated Rejection: Defective syringes are automatically removed from the production line, ensuring only qualified products move forward.

This integration of AI and imaging significantly reduces human error, speeds up inspection, and ensures consistent results at high volumes.

Benefits for Pharmaceutical Manufacturers

Enhanced Drug Quality – Ensures that every syringe delivered to patients is free from contamination and defects.

Reduced False Detection Rates – Proprietary algorithms distinguish bubbles from particles, minimizing unnecessary product waste.

Improved Efficiency – Automated de-nesting and re-nesting reduce manual handling and speed up production.

Regulatory Compliance – Meets stringent global standards for sterile injectable products.

Cost Savings – By preventing recalls and reducing waste, the machine lowers long-term operational costs.

Contribution to Patient Safety

Ultimately, the purpose of the Pre-filled Syringe Inspection Machine is to safeguard patients. Each inspected syringe reduces the risk of contaminated or defective drugs reaching end users. With growing reliance on injectable therapies worldwide, SANTUO’s innovation ensures patients receive safe, effective, and reliable treatments every time.

Conclusion

In today’s pharmaceutical landscape, ensuring drug quality is not just a compliance requirement—it is a moral responsibility. Pre-filled syringes offer convenience and accuracy, but without proper inspection, they can introduce safety risks. The Pre-filled Syringe Inspection Machine by SANTUO provides a comprehensive solution with its intelligent closed-loop process of “de-nesting → inspection → re-nesting.” From bubble elimination to defect detection, AI-driven analysis, and precise handling, it delivers all-round protection for drug quality.

By integrating this advanced technology into production lines, pharmaceutical manufacturers can achieve higher efficiency, stronger compliance, and most importantly—greater patient safety.