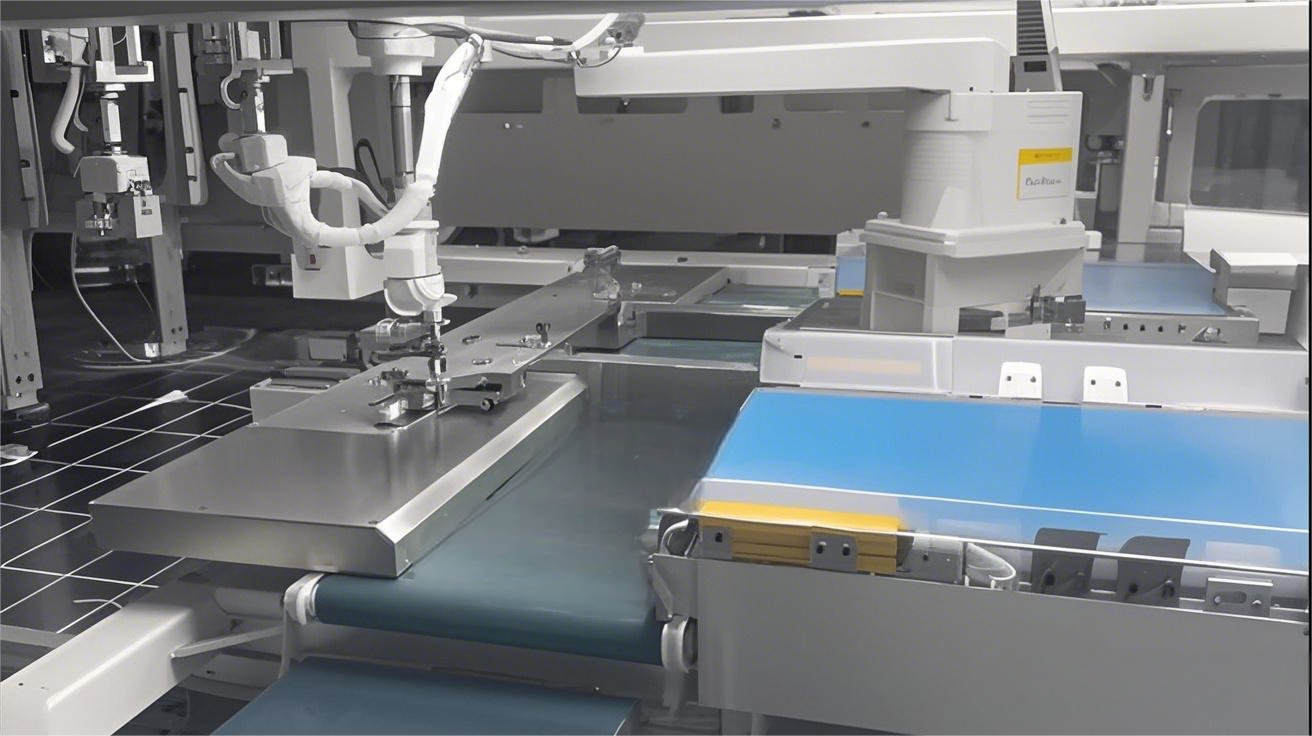

In the rapidly evolving solar industry, manufacturing efficiency and product reliability are the twin pillars of success. As photovoltaic (PV) modules become increasingly advanced, the demand for intelligent, automated, and high-precision assembly equipment continues to rise. Among these technologies, the Junction Box Installation Machine has become a cornerstone of modern PV production lines — ensuring consistent quality, optimized throughput, and adaptable compatibility across diverse module types.

Bluemann, a leading innovator in photovoltaic equipment manufacturing, has developed a next-generation Junction Box Installation Machine that perfectly meets these industrial needs. Engineered for speed, precision, and versatility, it represents a significant leap forward in the automation of solar module assembly.

1. Understanding the Role of Junction Box Installation in PV Module Manufacturing

A junction box is one of the most crucial components in any solar module. It serves as the electrical interface that connects the solar cell array to external circuits, ensuring stable current flow and long-term operational safety. Traditionally, junction box installation was a semi-automated or manual process that required skilled labor and meticulous attention to detail. Even minor alignment errors could compromise electrical performance or reduce module durability.

To eliminate human error and enhance consistency, manufacturers increasingly rely on automated junction box installation machines. These machines not only guarantee precise placement but also ensure strong adhesion and reliable electrical connectivity — factors essential to module performance and longevity.

2. Bluemann’s Junction Box Installation Machine: A Breakthrough in Solar Automation

Bluemann’s Junction Box Installation Machine is designed to meet the demands of all mainstream PV module types, offering full adaptability to different cell spacings and junction box designs. It integrates high-precision positioning systems, intelligent vision alignment, and fully automated adhesive dispensing to ensure each junction box is installed with exacting accuracy.

Key advantages include:

Universal Compatibility:

The machine accommodates various module dimensions, backsheet materials, and junction box structures. Whether for half-cell, bifacial, or shingled modules, Bluemann’s system ensures perfect fitment and consistent adhesion.

Precision and Repeatability:

Advanced servo control and visual guidance technologies guarantee sub-millimeter positioning accuracy, reducing alignment errors that can affect electrical contact or sealing integrity.

Automated Adhesive Control:

Bluemann integrates intelligent glue dispensing systems that monitor viscosity, volume, and pattern. This ensures uniform adhesive application — a critical factor for both bonding strength and long-term moisture resistance.

High-Speed Operation:

With optimized motion control and automated module transfer, the installation cycle time is drastically reduced. This helps manufacturers increase productivity while maintaining superior quality standards.

Real-Time Monitoring and Traceability:

The system includes comprehensive process monitoring, error detection, and data logging capabilities. Every junction box installation can be traced, ensuring full transparency and easier quality audits.

3. Customization for Different Module Configurations

What truly sets Bluemann apart is its machine’s customization capability. Since PV module types vary by cell layout, backsheet thickness, and electrical design, one-size-fits-all solutions are no longer sufficient. Bluemann’s engineering team tailors the junction box installation parameters — such as pressing force, curing time, and positioning speed — based on the client’s production specifications.

This level of customization allows the Junction Box Installation Machine to integrate seamlessly into different module assembly lines, from high-volume mass production to specialized, small-batch manufacturing.

For manufacturers who deal with multiple module variants, the system’s quick-change fixtures and software profiles enable effortless switching between configurations, minimizing downtime and ensuring continuous operation.

4. Sustainability and Energy Efficiency in Manufacturing

Beyond performance and speed, Bluemann is also committed to sustainability. The Junction Box Installation Machine uses energy-efficient servo motors and low-waste adhesive dispensing technologies, reducing both operational costs and environmental impact.

Moreover, by ensuring perfect sealing and long-lasting junction box adhesion, the system contributes to enhanced durability of solar modules, directly supporting the global push toward renewable energy reliability and sustainability.

5. Why Choose Bluemann as Your Automation Partner

Partnering with Bluemann means more than purchasing a machine — it means gaining a long-term technology ally. Bluemann provides comprehensive technical support, from installation and operator training to remote diagnostics and performance upgrades.

With years of experience in solar equipment engineering, Bluemann continuously refines its solutions to match the latest advancements in PV manufacturing. Whether you’re optimizing an existing production line or building a new facility, Bluemann’s Junction Box Installation Machine ensures your operations remain at the cutting edge of solar innovation.

Conclusion: The Future of PV Module Assembly Starts Here

As the global solar industry continues to expand, efficiency, precision, and flexibility will define the next era of manufacturing excellence. Bluemann’s Junction Box Installation Machine embodies all these qualities, delivering a robust, adaptable, and intelligent solution for modern photovoltaic production lines.

By combining advanced automation, data intelligence, and energy efficiency, Bluemann empowers manufacturers to achieve higher throughput, lower defects, and superior long-term reliability — ensuring every solar module performs flawlessly from the factory floor to the field.