Let's consider the unsung heroes, the silent workhorses that power our increasingly automated world: heavy-duty connectors. Imagine the relentless environments where technology pushes boundaries – the scorching heat of a desert oil rig, the bone-jarring vibrations of a factory floor, the crushing depths of undersea exploration. What keeps the power, data, and signals flowing reliably through it all? The answer, more often than not, lies in these robust components.

These are *not* your average plugs. Forget the flimsy plastic of a phone charger; heavy-duty connectors are specialized electrical titans, forged to withstand extreme heat, biting humidity, abrasive dust, corrosive water, relentless vibration, and the general mechanical mayhem that defines heavy industry. They are the robust backbone upon which modern industry leans, ensuring everything from the precise movements of robotic arms to the steady hum of wind turbines. Their importance is reflected in the market size: a multi-billion dollar industry, estimated around $3.4-$3.6 billion in 2023, and poised for continued expansion.

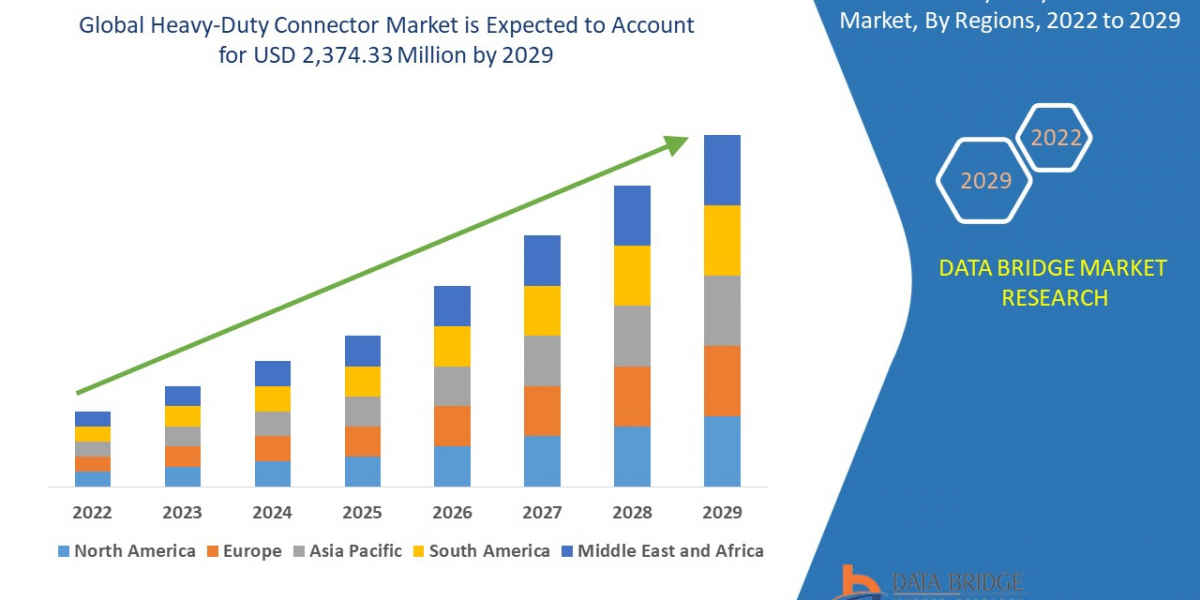

Databridge Market Research took a dive into comprehensively analyzing the market and unveiled that the Global Heavy Duty Connector Market increasing at a CAGR of 4.55%. The size of the market is valued at USD 1.89 billion in 2023 and is expected to grow up to USD 2.58 billion by 2031.

II. From Taped Wires to Smart Systems: A Journey Through Time

Contemplate for a moment the primitive origins from which these sophisticated devices evolved. Once upon a time, in the nascent days of electrical engineering, connections were little more than wires twisted together and haphazardly insulated with tape. As industry burgeoned in the early to mid-20th century, the inadequacy of such crude methods became glaringly apparent. Industrial growth thundered a resounding, "Nope, not good enough!"

This realization sparked a wave of innovation and, crucially, standardization. The 1930s through the 1950s witnessed the rise of pioneering companies like ITT Cannon, who envisioned and brought forth the first aircraft connector, followed by the versatile D-Subminiature connector. Connectors were no longer mere haphazard bits of metal; they became engineered components. HTS, now known as TE Connectivity, began specializing in robust rectangular connectors, responding to and further solidifying the demand for durability in demanding industrial applications.

The narrative then becomes one of continuous refinement. The early 1960s saw the introduction of crimping technology, liberating engineers from the messy and often unreliable process of soldering, particularly crucial in high-temperature environments. The 1990s heralded the era of modularity; as machines grew in complexity, connectors needed to adapt. HARTING's Han-Modular series led this charge, enabling the combination of power, data, and even pneumatic lines into a single, elegantly integrated package. Efficiency reigned supreme.

Recent decades have witnessed further leaps forward. Push-in technology has expedited installation processes and enhanced vibration resistance. Materials have undergone a dramatic transformation; while metal once reigned supreme, high-quality, eco-friendly plastics are now challenging its dominance. Furthermore, advanced alloys and aluminum are employed to shed weight without sacrificing performance. The Internet of Things (IoT) has further catalyzed miniaturization and high-density designs. And perhaps most fascinatingly, we are on the cusp of the "smart" connector revolution. Industry 4.0 demands more than just passive connections; connectors are now being imbued with integrated electronics and sensors, enabling real-time data acquisition, predictive maintenance capabilities, and high-speed information flow. Even wireless connectors are emerging on the horizon, promising even greater flexibility and adaptability.

https://www.databridgemarketresearch.com/reports/global-heavy-duty-connector-market

III. The Industrial Powerhouses: Where HDCs Are Kicking Butt Today

Consider the vast landscape where heavy-duty connectors prove their mettle daily. The reigning champions, without a doubt, are the industrial equipment and manufacturing sectors. Robots, automated assembly lines, the intricate dance of Industry 4.0 – these applications are insatiable in their demand for reliable connectivity.

But their influence extends far beyond the factory floor. Examine the realm of transportation. Electric vehicles, with their high-voltage demands, depend on HDCs. Trains, planes, ships – any mode of transportation that relies on electrical power invariably relies on these connectors. Then there's the burgeoning energy sector. Solar panels, wind turbines, offshore oil rigs – these harsh environments demand connectors capable of withstanding extreme conditions. Even the act of building itself, the operation of heavy construction machinery, is underpinned by the reliability of HDCs. And finally, ponder the expansion of connectivity itself. The rollout of 5G networks and the infrastructure of telecommunications rely on the steadfast performance of heavy-duty connectors.

This pervasive adoption is driven by powerful global trends: the relentless march of automation, the proliferation of smart factories, the global transition to renewable energy sources, and the explosive growth of electric vehicle infrastructure. Asia-Pacific stands as the undisputed heavyweight champion, fueled by rapid industrialization, while North America remains a significant player thanks to its robust technology sector and substantial infrastructure investments. Experts consistently characterize HDCs as a "foundational technology," critical for both modernizing existing industries and electrifying the world around us. While the landscape evolves, metal connectors continue to dominate, providing the ultimate robustness in the most challenging applications.

IV. The Bumpy Road: What's Challenging the Connector Kings?

Yet, the path ahead is not without its obstacles. The very attribute that defines them – their heavy-duty nature – often translates to a "heavy cost." This inherent price sensitivity becomes a significant consideration, particularly when faced with the allure of cheaper, albeit less reliable, alternatives.

Moreover, their installation is not always a straightforward "plug-and-play" affair. Complex setups, coupled with the risk of human error during installation, can lead to escalating maintenance costs. Adding to the complexity is the intricate web of regulations – stringent safety standards, electromagnetic compatibility requirements, and industry-specific norms that necessitate constant testing and certification.

The absence of harmonized global standards introduces further friction. The lack of interoperability can complicate manufacturing processes and decision making for buyers. Supply chain vulnerabilities, exacerbated by events like the COVID-19 pandemic, can disrupt raw material prices (particularly for metals) and cause delays, squeezing profit margins. Finally, a tendency towards custom designs tailored to specific systems can hinder economies of scale.

Browse More Reports:

Europe Walk-In Refrigerators and Freezers Market

Europe Session Initiation Protocol (SIP) Trunking Services Market

Middle East and Africa Predictive Maintenance Market

Europe Functional Mushroom Market

North America Functional Mushroom Market

North America Automated Liquid Handling Market

Global Hyperbaric Oxygen Therapy (HBOT) Market

Global Digital Forensics Market

Global Functional Mushroom Market

Global Electron Microscope Market

Global Track and Trace Solutions Market

Global Mass Spectrometry Market

Global Tallow Market

Global Atherosclerosis Market

Global Active, Smart and Intelligent Packaging Market

V. Future-Proofing Connections: What's Next for HDCs?

Despite these challenges, the future for heavy-duty connectors remains undeniably bright. Expect continued robust growth, propelled by the forces of automation, smart systems, electric vehicles, and the global push towards green energy initiatives.

The "smart" evolution will only accelerate. Connectors will transcend their traditional role as mere conduits of power, evolving into integrated "smart hubs" capable of transmitting real-time data, enabling remote diagnostics, and paving the way for predictive maintenance strategies. Designs will be further refined to achieve even greater degrees of sealing and resistance to extreme conditions. Miniaturization and modularity will advance, facilitating seamless integration and enabling higher voltage, current, and data speeds. Sustainability will become increasingly paramount, driving the adoption of eco-friendly, recyclable materials and energy-efficient designs. Contactless, wireless solutions are also poised to emerge, promising enhanced mobility and reduced wear and tear.

Asia-Pacific will likely maintain its leading position in the market, with North America close behind. Manufacturing will remain the largest segment, and metal connectors will continue to hold their ground as the preferred choice for applications demanding the utmost durability. In essence, these unsung heroes are not merely surviving; they are evolving at warp speed, ensuring our increasingly complex, automated, and sustainable future remains reliably connected.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com