"Global Executive Summary Aluminum Welding Market: Size, Share, and Forecast

CAGR Value

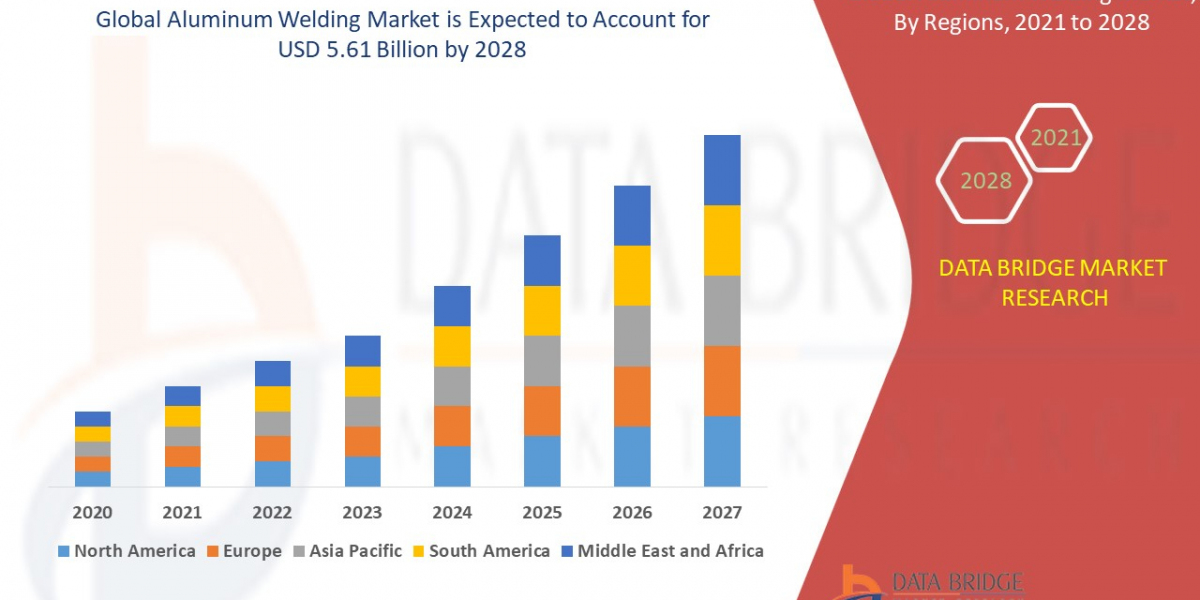

The global aluminum welding market size was valued at USD 4.47 billion in 2024 and is projected to reach USD 7.02 billion by 2032, with a CAGR of 5.80% during the forecast period of 2025 to 2032

While preparing the first class Aluminum Welding Market report, all the necessities and requirements of the businesses have been considered with which they can achieve successful business growth. All the data, statistics, facts and figures included in this report are very vital to the businesses when it comes to define the strategies about the production, Market, sales, promotion, advertising and distribution of the products and services. The large-scale Aluminum Welding Market analysis report also endows with an insightful overview of product specification, technology, product type and production analysis by taking into account most important factors such as revenue, cost, and gross margin.

Aluminum Welding Market research report performs an estimation of the growth rate and the market value based on market dynamics and growth inducing factors. A variety of steps are employed while generating this report and the inputs from a specialized team of researchers, analysts and forecasters have been utilized here. Besides, the report is wonderfully characterized using several charts, graphs and tables depending on the extent of data and information involved. Clients can divulge best opportunities to be successful in the Aluminum Welding Market industry with an excellent practice models and method of research used in the consistent Aluminum Welding Market report.

Stay ahead with crucial trends and expert analysis in the latest Aluminum Welding Market report.Download now:

https://www.databridgemarketresearch.com/reports/global-aluminum-welding-market

Aluminum Welding Industry Overview

Segments

- By Type: The global aluminum welding market can be segmented based on type into gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), flux-cored arc welding (FCAW), and others. Each type offers distinct advantages in terms of efficiency, precision, and applicability to different aluminum welding applications.

- By Application: Aluminum welding finds extensive applications in industries such as automotive, aerospace, construction, marine, and others. The increasing demand for lightweight and durable materials in these sectors is driving the growth of the aluminum welding market across various applications.

- By Region: Geographically, the global aluminum welding market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America and Europe are prominent markets due to the presence of established automotive and aerospace industries. Meanwhile, the Asia Pacific region is witnessing rapid growth driven by infrastructure development and industrialization.

Market Players

- The Lincoln Electric Company

- ESAB

- Ador Welding Ltd.

- Fronius International GmbH

- Illinois Tool Works Inc.

- Air Liquide

- Kobe Steel, Ltd.

- Amada Miyachi America, Inc.

- The Harris Products Group

- Muller Welding

- Dynaweld

These market players are actively involved in product development, strategic partnerships, and mergers and acquisitions to enhance their market presence and gain a competitive edge in the global aluminum welding market. With a focus on technological advancements and innovation, these companies are catering to the evolving demands of various industries that rely on aluminum welding processes.

The global aluminum welding market is poised for significant growth owing to the increasing adoption of aluminum as a preferred material in diverse industries. Factors such as lightweight properties, corrosion resistance, and high strength-to-weight ratio make aluminum an attractive choice for manufacturers looking to improve product performance and durability. Additionally, stringent regulations related to emissions and fuel efficiency are driving the demand for aluminum welding in the automotive and aerospace sectors.

As technology continues to advance, the market is witnessing a shift towards automation and robotics in aluminum welding processes. This trend is expected to streamline operations, increase efficiency, and ensure consistent quality in the welding of aluminum components. Moreover, the growing emphasis on sustainability and environmentally friendly practices is influencing manufacturers to adopt efficient welding techniques that minimize waste and energy consumption.

Overall, the global aluminum welding market is characterized by intense competition, innovation, and rapid technological advancements. Market players are focusing on expanding their product portfolios, enhancing operational capabilities, and strengthening their distribution networks to meet the evolving needs of customers worldwide. With the increasing demand for aluminum welding solutions across various industries, the market is projected to witness steady growth in the coming years.

The global aluminum welding market is set to experience robust growth driven by various key factors. One of the primary drivers is the increasing adoption of aluminum across industries due to its lightweight properties, corrosion resistance, and high strength-to-weight ratio. Manufacturers are increasingly turning to aluminum as a preferred material to enhance product performance and durability. Industries such as automotive, aerospace, construction, marine, and others are leveraging aluminum welding processes to meet the demand for lightweight and durable materials. This trend is expected to propel the growth of the aluminum welding market in the coming years.

Furthermore, stringent regulations related to emissions and fuel efficiency are playing a significant role in driving the demand for aluminum welding in sectors like automotive and aerospace. With a growing focus on sustainability and environmental-friendly practices, manufacturers are increasingly adopting efficient welding techniques that minimize waste and energy consumption. This shift towards sustainability is reshaping the aluminum welding market and pushing companies to innovate and develop new solutions that align with these emerging trends.

Moreover, the market is witnessing a rapid shift towards automation and robotics in aluminum welding processes. Automation is helping streamline operations, enhance efficiency, and ensure consistent quality in the welding of aluminum components. This adoption of automation is likely to transform the industry, leading to improved productivity and cost-effectiveness. Companies are investing in technological advancements to keep pace with these changes and optimize their manufacturing processes.

In terms of market players, companies like The Lincoln Electric Company, ESAB, Ador Welding Ltd., Fronius International GmbH, and others are actively engaged in product development and strategic partnerships to strengthen their market presence. These players are focusing on expanding their product portfolios and enhancing their operational capabilities to cater to the evolving needs of customers worldwide. By investing in innovation and technology, market players are positioning themselves to gain a competitive edge in the global aluminum welding market.

Overall, the global aluminum welding market is characterized by intense competition, rapid technological advancements, and a growing emphasis on sustainability. With the increased adoption of aluminum across industries and the shift towards automation, the market is poised for steady growth in the foreseeable future. Companies that can effectively innovate, adapt to changing market dynamics, and meet the evolving demands of customers are likely to thrive in this competitive landscape.The global aluminum welding market is experiencing significant growth driven by several key factors that are reshaping the industry landscape. The increasing adoption of aluminum in various industries is a primary driver, attributed to its lightweight properties, corrosion resistance, and high strength-to-weight ratio. Manufacturers are turning to aluminum as a preferred material to improve product performance and durability, especially in sectors like automotive, aerospace, construction, and marine. This rising demand for lightweight and durable materials is fueling the growth of the aluminum welding market globally.

Moreover, stringent regulations concerning emissions and fuel efficiency are playing a crucial role in boosting the demand for aluminum welding, particularly in automotive and aerospace applications. With a growing focus on sustainable practices, manufacturers are embracing efficient welding techniques that reduce waste and energy consumption. This sustainability trend is compelling companies to innovate and develop environmentally friendly solutions to align with evolving market demands.

The market is also witnessing a significant shift towards automation and robotics in aluminum welding processes. Automation is enhancing operational efficiency, ensuring consistent quality, and streamlining production operations. The adoption of automation is driving improvements in productivity and cost-effectiveness, leading to transformative changes in the industry. Market players are investing in technological advancements to stay competitive and optimize their manufacturing processes.

In the competitive landscape of the aluminum welding market, key players such as The Lincoln Electric Company, ESAB, Ador Welding Ltd., Fronius International GmbH, and others are actively engaged in product development and strategic partnerships. These companies are expanding their product portfolios, enhancing operational capabilities, and strengthening their market presence to cater to the evolving needs of customers worldwide. By focusing on innovation and technology, these market players are positioning themselves to gain a competitive edge and meet the dynamic requirements of the aluminum welding market.

Overall, the global aluminum welding market is characterized by intense competition, rapid technological advancements, and a growing emphasis on sustainability. With the increasing adoption of aluminum across industries, coupled with the shift towards automation, the market is poised for steady growth in the foreseeable future. Companies that can effectively innovate, adapt to changing market dynamics, and address the evolving demands of customers are likely to thrive in this competitive environment.

Access detailed insights into the company’s market position

https://www.databridgemarketresearch.com/reports/global-aluminum-welding-market/companies

Alternative Research Questions for Global Aluminum Welding Market Analysis

- How is the current market size of the Aluminum Welding Market industry quantified?

- What is the long-term growth forecast for the market?

- What subcategories or sectors are addressed in the report?

- Which companies dominate the Aluminum Welding Market today?

- What new product strategies are being adopted by leaders?

- What countries’ markets are included in the study?

- What is the top-growing region identified in the Aluminum Welding Market report?

- Which country will dominate revenue-wise?

- What region currently holds the leading market position?

- What nation is expected to record the strongest CAGR for Aluminum Welding Market?

Browse More Reports:

Asia-Pacific Grape Seed Extract Market

Europe Grape Seed Extract Market

Middle East and Africa Grape Seed Extract Market

Asia-Pacific Glioblastoma Multiforme Treatment Market

Europe Glioblastoma Multiforme Treatment Market

Middle East and Africa Glioblastoma Multiforme Treatment Market

North America Glioblastoma Multiforme Treatment Market

Asia-Pacific Full Body Scanner Market

Europe Full Body Scanner Market

Middle East and Africa Full Body Scanner Market

North America Full Body Scanner Market

North America Forestry Equipment Market

Asia-Pacific Forestry Equipment Market

Middle East and Africa Forestry Equipment Market

Asia-Pacific Feed Flavor and Sweetener Ingredients Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"