1. Introduction

The Global Optical Coating Market involves the specialized application of thin films onto optical components (such as lenses, mirrors, and displays) to manipulate their interaction with light. These coatings, typically composed of dielectric or metallic materials, are crucial for enhancing performance by controlling reflection, transmission, absorption, and polarization across the electromagnetic spectrum (UV, Visible, and IR).

The market is essential to the functionality of modern technology, spanning consumer devices, high-precision scientific instruments, and cutting-edge defense systems.

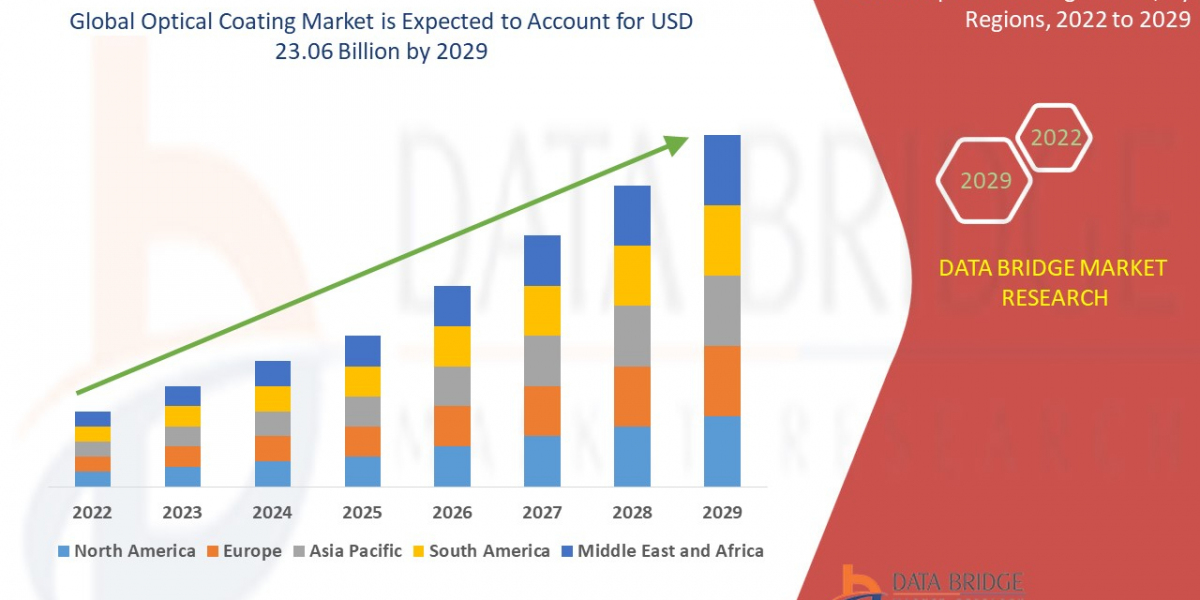

Global optical coating market size was valued at USD 15.81 billion in 2024 and is projected to reach USD 28.93 billion by 2032, with a CAGR of 7.85% during the forecast period of 2025 to 2032.

2. Market Dynamics

2.1. Market Drivers

Booming Consumer Electronics Sector: Rapid growth in the demand for smartphones, tablets, smart wearables, and advanced displays (OLED/LED) drives the need for Anti-Reflective (AR), anti-scratch, and easy-to-clean coatings to improve display clarity and durability.

Expansion of the Solar PV Market: Optical coatings, particularly AR coatings, are crucial for maximizing the efficiency of photovoltaic (PV) solar panels by minimizing surface reflection and increasing light transmission, fueled by global renewable energy initiatives.

Technological Advancements in Automotive Electronics: The integration of advanced driver assistance systems (ADAS), LiDAR sensors, heads-up displays (HUDs), and sophisticated lighting systems in modern vehicles heavily relies on high-performance optical coatings for safety and functionality.

Increased Demand in Healthcare and Defense: The medical sector requires precise coatings for diagnostic equipment, endoscopes, and laser systems, while the defense/aerospace industry demands durable, high-laser-damage-threshold coatings for military optics and satellite components.

2.2. Market Restraints & Challenges

Volatile Raw Material Prices: The cost of key coating materials (like titanium dioxide, gold, silver, and rare earth oxides) can fluctuate significantly, impacting manufacturing costs and profitability.

High Complexity and Cost of Equipment: Advanced deposition technologies (like Ion-Assisted Deposition and Sputtering) require expensive, high-vacuum equipment and highly specialized operators, leading to high capital expenditure.

Stringent Performance Requirements: Meeting highly specific and precise coating specifications (e.g., ultra-narrowband filters or extremely low-loss coatings) for advanced photonics can be challenging and complex.

3. Market Segmentation

The market can be segmented based on the function of the coating, the technology used for application, and the end-use industry.

| Segmentation Category | Leading Segment | Key Alternative Segments |

| By Product Type | Anti-Reflective Coatings (Largest Revenue Share) | High-Reflective, Filter, Transparent Conductive, Electrochromic Coatings |

| By Technology | Vacuum Deposition (PVD/CVD) | Sputtering Process, E-Beam Evaporation, Ion-Assisted Deposition (IAD) |

| By End-Use Industry | Consumer Electronics (Largest Revenue Share) | Telecommunications, Automotive, Solar Power, Medical, Aerospace & Defense |

Segment Insights:

Anti-Reflective (AR) Coatings dominate as they are widely used across almost all major applications, from eyeglasses and camera lenses to displays and solar panels, to maximize light throughput and visual clarity.

The Consumer Electronics segment is the largest end-user, but the Solar and Automotive segments are poised for the fastest growth rates due to regulatory pressure and technological integration.

https://www.databridgemarketresearch.com/reports/global-optical-coatings-market

4. Regional Insights

| Region | Market Status | Key Growth Drivers |

| Asia-Pacific (APAC) | Largest Market Share (or Fastest Growing, depending on source) | Dominance of electronics manufacturing (China, South Korea, Japan), huge solar energy investments (China, India), and expanding middle-class demand for smartphones and display technology. |

| North America | Leading in Innovation and High-End Applications | Strong presence of defense, aerospace, and medical device companies; robust semiconductor and photonics research; and growing domestic solar manufacturing. |

| Europe | Steady Growth, Driven by Automotive and Green Building | High demand for automotive displays, sensors, and lighting; focus on energy-efficient architectural glass (low-emissivity coatings); and strong R&D in optics. |

5. Competitive Landscape

The global optical coating market is characterized by a mix of large, diversified chemical/materials giants and specialized, high-precision optics firms. Competition revolves around coating quality, precision, cost-effectiveness, and the ability to customize for highly specific wavelength and angular requirements.

| Leading Market Players | Key Areas of Specialization |

| DuPont | Specialty materials, AR coatings for displays and electronics. |

| PPG Industries, Inc. | Automotive and architectural glass coatings (anti-UV, abrasion resistance). |

| ZEISS Group | High-precision coatings for lithography optics, medical devices, and camera lenses. |

| Nippon Sheet Glass Co., Ltd. (NSG) | Automotive and architectural glass, solar energy applications. |

| Coherent Corp. | Laser-grade and high-damage-threshold coatings for industrial and scientific lasers. |

| MKS Instruments (Newport) | Scientific research, semiconductor, and defense applications. |

6. Future Outlook

The future of the optical coating market is tied directly to the advancement of high-tech industries and the shift towards energy efficiency.

Meta-Surfaces and Nano-Coatings: The emergence of meta-surface technology (nano-patterned coatings) promises to replace bulky, multi-layer conventional coatings with ultra-thin, high-performance films, particularly in Augmented Reality (AR) and Virtual Reality (VR) waveguides and advanced sensor optics.

Roll-to-Roll Processing: Development of more scalable, cost-effective, and high-throughput coating methods, such as Atmospheric Plasma Deposition and improved roll-to-roll (R2R) vacuum deposition, will lower the cost barrier for mass-market applications.

Green Coatings: Increasing regulatory pressure will accelerate the transition towards eco-friendly and solvent-free coating materials and processes, reducing the environmental footprint of coating production.

EUV Lithography: The production of next-generation semiconductor chips relies on Extreme Ultraviolet (EUV) lithography, requiring ultra-precise, high-reflectivity multilayer mirror coatings, driving growth in the high-end specialty segment.

Browse More Reports:

Global Radiofrequency (RF) Micro needling Market

Global Radio Immunoassay (RIA) Reagents and Devices Market

Global Robotic Endoscopy Devices Market

Global GAN Epitaxial Wafers Market

Global Intranasal Antidepressant Market

Global Polybutadiene Market

Global Vestibular Neuronitis Treatment Market

Global Vitamin Deficiency Treatment Market

Global Automotive Bicycle Chain Market

Global Business Process Management (BPM) in Real Estate Market

Global Orthopaedic Imaging Equipment Market

Global Water Based Heliports Market

Global Medical Kits Market

Global Needle Destroyer Market

Global Makeup Tools Market

7. Conclusion

The Global Optical Coating Market is a high-growth sector, foundational to the electronics, energy, and defense industries. Sustained expansion is guaranteed by the relentless demand for higher performance, greater efficiency, and enhanced durability in consumer devices and industrial optics. While manufacturers must navigate challenges related to raw material cost volatility and technological complexity, the innovation pipeline, particularly in areas like anti-reflective coatings and advanced deposition techniques, ensures robust market vitality for the foreseeable future.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com