1. Introduction

The Global Predictive Maintenance (PdM) Market involves the adoption of advanced technologies—primarily the Internet of Things (IoT), Artificial Intelligence (AI), and Machine Learning (ML)—to monitor the condition of equipment and predict when maintenance should be performed. This proactive approach allows organizations to schedule necessary maintenance at the most opportune time, just before a failure is likely to occur, rather than performing fixed-schedule preventive maintenance or reacting to breakdowns.

PdM is a cornerstone of the global Industry 4.0 movement, offering significant benefits in terms of operational efficiency, cost reduction, and asset longevity.

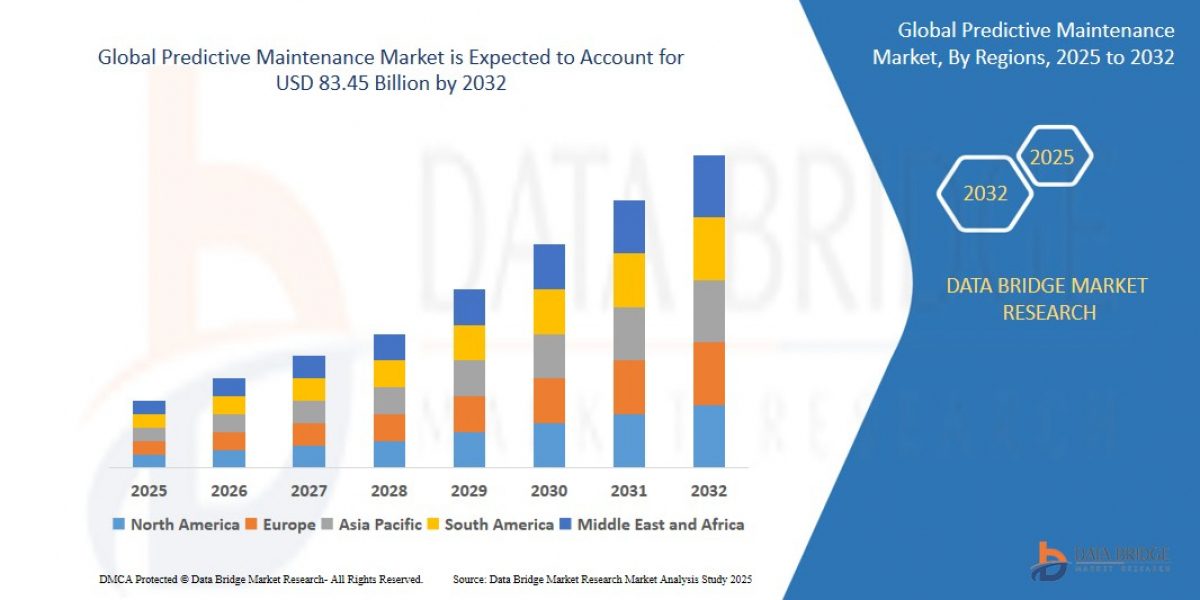

The global predictive maintenance market size was valued at USD 8.89 billion in 2024 and is expected to reach USD 83.45 billion by 2032, at a CAGR of 32.30% during the forecast period

2. Market Dynamics

2.1. Market Drivers

Focus on Operational Efficiency & Cost Reduction: The primary driver is the proven ability of PdM to deliver high ROI, including reductions in unplanned downtime (up to 75%), maintenance costs (up to 30%), and extensions in equipment life (up to 20%).

Advancements in IIoT and Sensor Technology: The proliferation and miniaturization of cost-effective, wireless IoT sensors (for monitoring vibration, temperature, pressure, etc.) and the increasing availability of high-bandwidth connectivity enable real-time data collection from industrial assets.

Integration of AI and Cloud Computing: Sophisticated AI and ML algorithms are essential for analyzing massive streams of sensor data to accurately predict failure patterns. The scalability, reduced cost, and remote accessibility offered by cloud platforms (like AWS, Azure, Google Cloud) significantly ease the deployment of these complex solutions.

Complex Industrial Assets: Modern industrial equipment is highly complex, making traditional maintenance insufficient. PdM is necessary to ensure the continuous uptime of high-value assets in sectors like manufacturing and energy.

2.2. Market Restraints & Challenges

High Initial Investment: The cost of installing new sensors, implementing the necessary IT infrastructure, and licensing advanced software platforms represents a significant upfront burden, especially for Small and Medium-sized Enterprises (SMEs).

Data Security and Interoperability: Organizations, particularly those using on-premise solutions, have deep concerns over the security and privacy of sensitive operational data. Furthermore, integrating new PdM systems with existing legacy Operational Technology (OT) infrastructure can be technically challenging.

Shortage of Skilled Personnel: There is a global shortage of professionals with the requisite hybrid skills—combining mechanical/domain expertise with data science and network security knowledge—needed to manage and interpret the output of complex PdM models.

3. Market Segmentation

The market is segmented to reflect the diverse technological and organizational requirements of end-users.

| Segmentation Category | Leading Segment (2024) | Fastest Growing Segment |

| By Component | Solutions (Software & Analytics) | Services (Consulting, Integration, Managed) |

| By Deployment Mode | On-Premise (Due to data control/security preference) | Cloud-Based (Due to scalability/cost) |

| By Organization Size | Large Enterprises (High IT budgets, large asset base) | Small and Medium-sized Enterprises (SMEs) |

| By Industry Vertical | Manufacturing | Energy & Utilities / Transportation & Logistics |

Segment Insights:

Component: While the Solutions segment (software and hardware) drives the core technology, the Services segment is growing fastest, highlighting the need for specialized expertise in data integration, model tuning, and ongoing system management.

Deployment: Though On-Premise dominates due to high data security demands in sectors like Manufacturing and Government, Cloud-Based deployment is accelerating due to its scalability and reduced total cost of ownership (TCO).

Industry Vertical: Manufacturing holds the largest share, driven by Industry 4.0 adoption. Energy & Utilities (grid modernization, turbine monitoring) and Transportation (fleet maintenance, rail assets) are experiencing high growth rates.

https://www.databridgemarketresearch.com/reports/global-predictive-maintenance-market

4. Regional Insights

| Region | Market Status | Key Drivers and Characteristics |

| North America | Largest Market Share | Dominance driven by early and aggressive adoption of IoT/AI, the presence of major technology providers (IBM, Microsoft, GE), and significant investment in aerospace, defense, and oil & gas sectors. |

| Asia-Pacific (APAC) | Fastest Growing Region | Fueled by massive investments in digital transformation, rapid industrialization, and the construction of new smart factories (especially in China, India, and South Korea). High growth in energy and utilities infrastructure. |

| Europe | Mature Market, Sustainability Focus | Strong regulatory emphasis on energy efficiency, safety, and sustainability (ESG), driving the adoption of PdM to optimize resource use and reduce emissions in manufacturing and infrastructure. |

5. Competitive Landscape

The Predictive Maintenance market is highly competitive, featuring a mix of large technology giants, industrial automation leaders, and specialized AI/analytics firms. Competition focuses on the accuracy of predictive models, platform integration capabilities, and industry-specific domain expertise.

| Company Type | Key Players | Strategic Focus |

| Technology/Cloud Giants | IBM, Microsoft (Azure), AWS, Google | Leveraging vast cloud infrastructure, AI/ML platforms, and digital twin technology. |

| Industrial Automation/IoT | Siemens AG, ABB, General Electric (GE), Honeywell | Deep domain expertise in industrial machinery; offering integrated hardware (sensors) and software platforms (e.g., Siemens MindSphere). |

| Enterprise Software | SAP SE, Oracle, SAS Institute, C3.ai | Integrating predictive analytics directly into ERP and Enterprise Asset Management (EAM) systems for seamless workflow optimization. |

6. Future Outlook

The market is expected to shift toward more sophisticated, autonomous, and integrated systems:

Prescriptive Maintenance: The evolution beyond predicting when a failure will occur to prescribing how to fix it, using AI to automatically generate and execute optimal maintenance work orders.

Digital Twins: Increased use of Digital Twin technology, which creates virtual models of physical assets, allowing for more accurate simulation of failure scenarios and real-time maintenance planning.

Edge Computing: A growing trend toward processing sensor data directly at the "edge" (near the equipment) rather than the cloud, enabling faster decision-making, reduced latency, and greater data security for critical assets.

Integration with AR/VR: Maintenance teams will utilize Augmented Reality (AR) headsets and tablets to overlay predictive data and prescriptive instructions onto physical equipment, boosting efficiency and first-time fix rates.

Browse More Reports:

Global Radiofrequency (RF) Micro needling Market

Global Radio Immunoassay (RIA) Reagents and Devices Market

Global Robotic Endoscopy Devices Market

Global GAN Epitaxial Wafers Market

Global Intranasal Antidepressant Market

Global Polybutadiene Market

Global Vestibular Neuronitis Treatment Market

Global Vitamin Deficiency Treatment Market

Global Automotive Bicycle Chain Market

Global Business Process Management (BPM) in Real Estate Market

Global Orthopaedic Imaging Equipment Market

Global Water Based Heliports Market

Global Medical Kits Market

Global Needle Destroyer Market

Global Makeup Tools Market

7. Conclusion

The Global Predictive Maintenance Market is undergoing exponential growth, driven by the compelling economic case for minimizing unplanned downtime and optimizing asset performance. By leveraging the convergence of IoT, AI, and cloud technology, PdM has moved from an aspirational technology to a mandatory operational strategy for asset-intensive industries worldwide. While addressing challenges related to data security and the skills gap is crucial, the long-term trajectory confirms PdM as the indispensable backbone of efficient, reliable, and intelligent industrial operations.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com