In modern job sites and remote installations, the outdoor electrical distribution panel often stands at the heart of uninterrupted energy management. When weather shifts or load demands rise, that enclosure ensures safe current flow to every connected tool and fixture without exposure. Yet its sturdy facade can conceal wear signs until issues escalate. Troubleshoot potential faults by watching for subtle hints like uneven enclosure temperatures or odd voltage drops at output terminals. Early detection prevents downtime and mitigates risks. Knowing when that distribution unit needs inspection can keep teams mobile and workflows smooth, reducing guesswork during urgent interventions. Learning simple evaluation steps empowers field crews to restore stable service with minimal delay and confusion.

A faint hum or intermittent flicker in lighting circuits may signal internal contact deterioration within that hardware. Dust intrusion or accumulated debris around seals can hinder performance. Examine terminal blocks for loose fittings, and test insulation integrity at each outlet point. Using portable diagnostic instruments, technicians can gauge electricity stability across feeders without full disassembly. Visual checks under moderate load reveal corrosion or discoloration near connectors. Addressing these elements promptly prevents arc faults or unexpected shutdowns. Regular patrols around service hubs let crews identify anomalies before enclosure replacement becomes unavoidable.

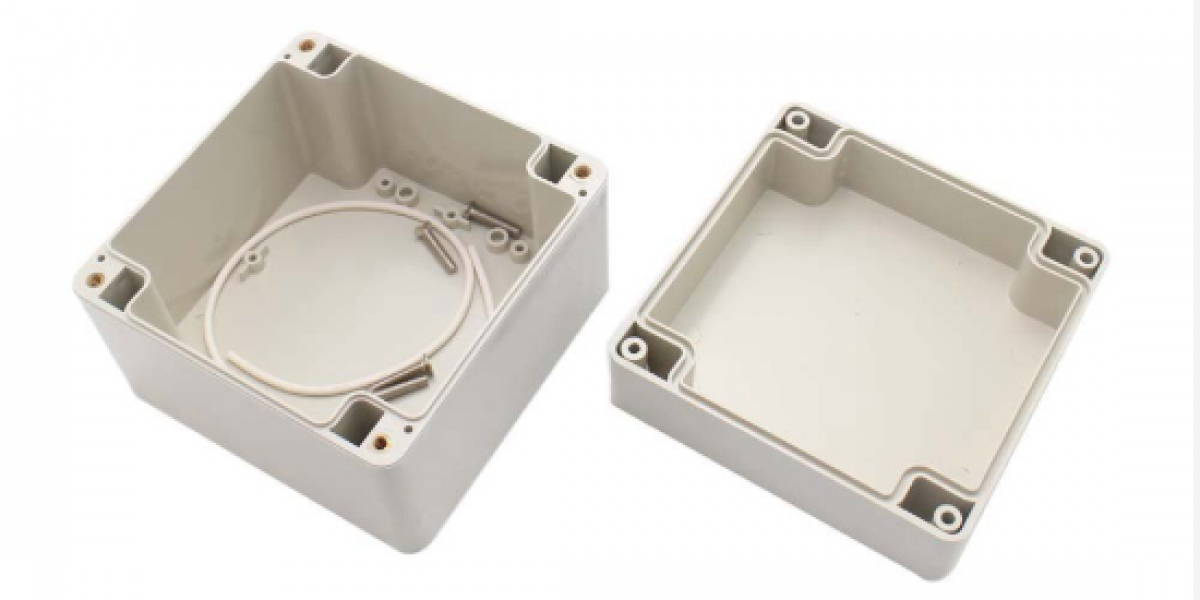

Moisture intrusion remains a frequent culprit behind erratic operation in exposed environments. Rain, dew, or high humidity can seep through failed gaskets or warped covers, creating conductive paths where they shouldn't exist. Inspect seals and latches at regular intervals, and replace any brittle rubber or cracked plastic components. A simple water test—observing for leaks after a light wash—can validate integrity without opening live circuits. Preventive measures like adding drip edges or small overhangs above units help divert moisture away from critical interfaces.

Rapid temperature swings pose another challenge for these distribution structures. Direct sun exposure during daytime heat, followed by cool night air, leads to expansion and contraction cycles that loosen internal fittings. Watch for hairline fractures in insulating materials or slight warping along panel edges. Discoloration around terminal areas often hints at hidden hotspots. If you spot darker patches or melted insulation, de-energize the section immediately and schedule a detailed examination of the internal busbars and mounting brackets.

Unexpected trips or nuisance resets may indicate terminal screws have vibrated loose or that protective mechanisms cannot handle surges. When breakers disengage without excessive load, inspect wiring clamps for tension loss. Low-resistance test methods help confirm conductor-to-lug contact remains sufficient under varying current draws. In many cases, retorquing connectors and cleaning contact surfaces with nonabrasive pads brings instant relief. If problems persist, consider swapping aged modules for newer types that better tolerate transient loads.

Physical impacts and accidental knocks can damage any outdoor power hub. Heavy equipment, service carts, or material handling vehicles brushing against the housing may dent or misalign doors. Even minor deformations break seal continuity and invite contaminants. Protect vulnerable edges with corner guards or set up buffer zones marked by safety tape. Teaching on-site personnel to respect clearance requirements minimizes collision risks and maintains the enclosure's defensive barrier.

Deciding between repair and full renewal requires weighing several indicators. If gasket replacements, hinge lubrication, and contact cleaning restore consistent performance, continued use makes sense. However, when multiple symptoms—sound anomalies, moisture infiltration, discoloration, and frequent trips—appear together, a modern replacement may offer lasting benefits. Newer models often include enhanced safeguards such as clearer internal layouts, improved seal designs, and easy-access service panels that streamline future maintenance tasks.

Consistent upkeep pays off in operational continuity and safety assurance. Field teams that perform routine walk-arounds, listen for unusual sounds, feel for temperature shifts, and look for discoloration stay ahead of faults. Coupling hands-on checks with simple electrical tests helps detect trouble before full disruption occurs. For asset managers seeking to optimize energy distribution and simplify upkeep, selecting a solution designed for resilience and service ease makes daily routines more predictable.

For professionals facing challenges with exterior distribution enclosures, Nante provides tailored options that blend sturdy construction with thoughtful service features. Exploring advanced designs and comprehensive support through the online catalog can transform how crews handle diagnostics and upkeep, turning reactive repairs into proactive maintenance practices. To learn more about specialized enclosures and streamlined intervention kits, visit https://www.nante.com/product/ .