The non woven fabric market has been witnessing significant growth across various regions due to its extensive usage in multiple end-use industries. Non woven fabrics are engineered materials made from fibres bonded together through mechanical, thermal, or chemical processes rather than traditional weaving or knitting. This manufacturing method provides versatility, cost-effectiveness, and enhanced performance characteristics, which are driving the market forward.

The major driving factor for the growth of the non woven fabric market is its increasing demand in the healthcare sector. The COVID-19 pandemic further highlighted the importance of non woven fabrics in manufacturing personal protective equipment such as surgical masks, gowns, caps, shoe covers, and medical packaging. These fabrics provide essential properties like breathability, absorbency, bacterial filtration, and barrier protection, making them ideal for medical applications. Even after the pandemic, the habit of using disposable hygienic products continues to grow, boosting market opportunities.

Apart from healthcare, non woven fabrics find extensive applications in the automotive industry. They are used in car interiors, insulation, filters, carpets, roof liners, seat linings, and hood liners. The automotive sector prefers non woven materials because they are lightweight, durable, and have noise absorption properties. The rising production of automobiles globally and the demand for premium, comfortable, and noise-free vehicles are further supporting the demand for non woven fabrics.

Hygiene products represent another significant segment for non woven fabrics. The increasing population, rising awareness about personal hygiene, and higher spending capacity among consumers are augmenting the usage of non woven fabrics in baby diapers, adult incontinence products, sanitary napkins, and wipes. Non woven fabrics used in these products offer softness, high absorption capacity, liquid repellency, and better comfort, making them preferable for manufacturers.

The construction industry is also contributing to the growth of the non woven fabric market. Non woven geotextiles are widely used in construction activities for soil stabilization, filtration, drainage, and erosion control. These fabrics provide high tensile strength, durability, and resistance to environmental conditions. With the rise in infrastructure development projects, especially in emerging economies, the demand for non woven geotextiles is increasing rapidly.

Additionally, non woven fabrics are gaining traction in the packaging sector due to their environmental benefits and cost-effectiveness. They are used for reusable shopping bags, gift packaging, protective packaging, and industrial packaging. The global focus on sustainability and reduction of single-use plastics has encouraged manufacturers to adopt non woven fabric bags as an eco-friendly alternative. The durability and reusability of non woven fabric bags attract both consumers and retailers.

From a production perspective, spunbond and meltblown technologies are widely adopted for manufacturing non woven fabrics. Spunbond fabrics have high tensile strength and durability, whereas meltblown fabrics offer fine filtration and barrier properties, making them ideal for medical and hygiene applications. Manufacturers are focusing on combining these technologies to create spunmelt fabrics, which provide enhanced features and performance, thus expanding their usage scope.

The market is witnessing technological advancements as manufacturers invest in research and development to improve fabric quality, reduce production costs, and introduce innovative products. Biodegradable non woven fabrics are gaining popularity as they reduce environmental pollution and meet the rising sustainability demands from governments and consumers. Many companies are working on bio-based and recycled non woven fabrics to attract eco-conscious customers.

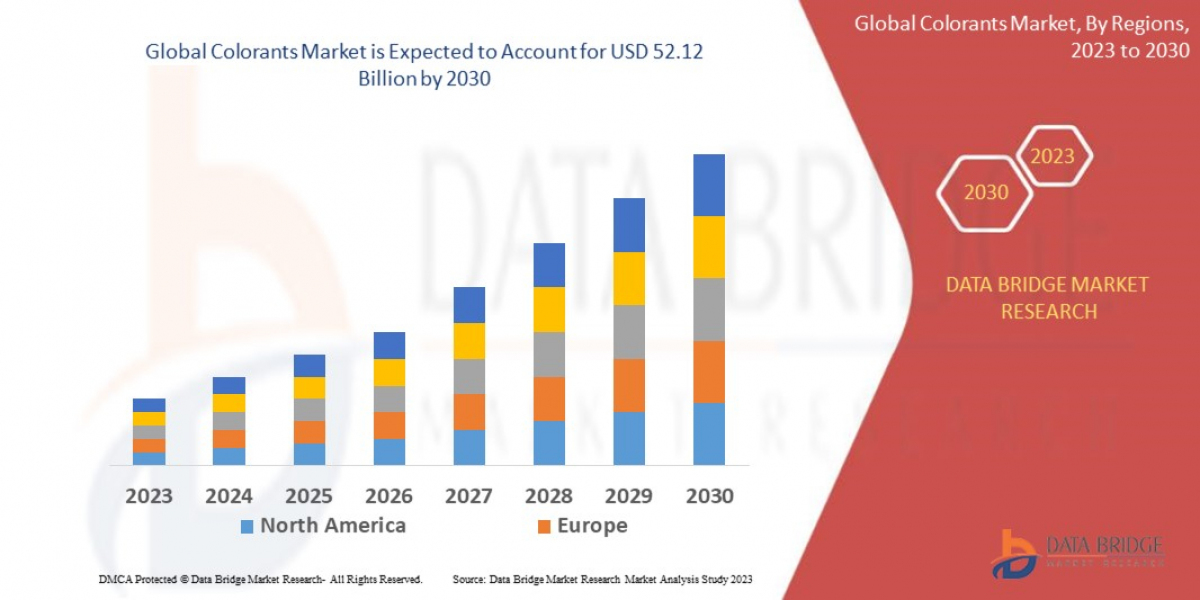

Regionally, Asia Pacific holds the largest share in the non woven fabric market due to the presence of high population countries such as China and India, which are major consumers of hygiene products, automotive, and construction materials. Moreover, low manufacturing costs, the presence of key players, and rising industrialization boost the market growth in this region. North America and Europe also contribute significantly due to their advanced healthcare infrastructure and stringent environmental regulations promoting eco-friendly products.

However, the market also faces certain challenges. The volatility in raw material prices, primarily polypropylene, affects production costs, leading to pricing issues for manufacturers and consumers. Additionally, the non biodegradable nature of conventional polypropylene-based non woven fabrics poses environmental concerns, which can hinder market growth if sustainability alternatives are not adopted promptly.

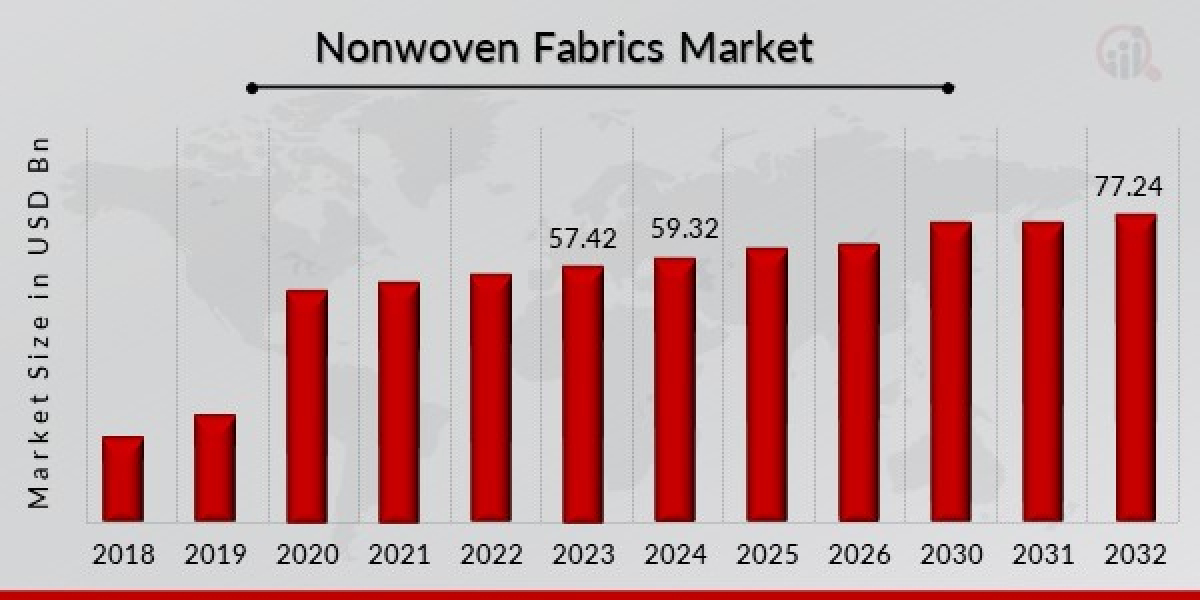

Despite these challenges, the future outlook for the non woven fabric market remains positive. The demand for disposable medical products, hygiene items, and automotive applications is expected to rise further. Moreover, the increasing focus on sustainable products and the development of biodegradable and bio-based non woven fabrics will create ample opportunities for market expansion. Manufacturers are also exploring advanced bonding technologies and surface treatments to enhance fabric functionalities, durability, and application range.