The mining explosives market has become one of the critical backbones of the global mining industry, playing a significant role in enhancing the efficiency of excavation and extraction activities. Mining explosives are chemicals used to break rocks and earth to extract minerals and metals beneath the surface. These explosives help achieve productivity, reduce manual efforts, and improve operational safety in mining environments. In recent years, with the rising demand for minerals, metals, and energy resources, the mining explosives market has experienced notable growth, driven by the expansion of mining activities worldwide.

One of the major factors propelling the mining explosives market is the increasing global demand for coal, iron ore, bauxite, and other metals essential for infrastructural, automotive, energy, and industrial sectors. Countries such as China, India, Australia, Russia, and the United States are among the largest consumers of mining explosives due to their high mining output. The market comprises various types of explosives, including bulk emulsions, ANFO (Ammonium Nitrate Fuel Oil), water gel explosives, and packaged explosives, each having specific applications based on mine depth, rock hardness, and extraction scale.

ANFO remains widely used in surface mining due to its cost-effectiveness and reliable detonation characteristics, while bulk emulsion explosives have gained popularity owing to their high energy and water resistance properties, making them suitable for both surface and underground mining operations. Additionally, packaged explosives are mainly used for controlled blasting and tunnelling operations where precise cutting is necessary. The advancement in explosive formulations and delivery technologies has enabled mining companies to achieve optimum fragmentation, reduce vibration, and minimise environmental impact during blasting operations.

Safety is an important aspect influencing the mining explosives market. Manufacturers are continuously innovating to develop safer and more environmentally friendly products. The integration of electronic detonators and digital blasting systems has improved blasting accuracy, reduced misfires, and enhanced overall operational safety in mines. Electronic detonators provide flexibility in blast timing, reduce ground vibration, and improve fragmentation results, ultimately reducing downstream processing costs for mining companies.

However, the mining explosives market also faces challenges, particularly in terms of stringent regulations and environmental concerns. The production, storage, transportation, and use of explosives are strictly regulated due to their hazardous nature. Governments worldwide have imposed safety standards to avoid accidents, theft, and misuse. Compliance with these regulations often increases operational costs for explosive manufacturers and mining companies. Moreover, environmental concerns regarding blasting emissions, vibration impacts on local communities, and ecological disturbances have compelled the industry to adopt sustainable and controlled blasting practices.

The market is witnessing technological advancements such as the use of drones for blast area inspection, automated delivery trucks for explosive placement, and digital blast design software that ensures precision and safety. These technological integrations enhance operational efficiency and reduce human exposure to hazardous zones, thereby promoting worker safety and productivity.

Another significant trend driving the mining explosives market is the expansion of underground mining activities. As surface deposits are depleting and becoming less economically viable, mining companies are shifting focus to deeper ore bodies, thereby increasing the demand for high-energy explosives and advanced blasting techniques suitable for underground mining environments. Underground mines require precise and controlled blasting to avoid damage to surrounding structures and ensure worker safety within confined spaces. This demand has encouraged manufacturers to develop low-fume, high-density, and high-energy explosives tailored for underground applications.

Furthermore, with the rise of infrastructural development projects globally, particularly in emerging economies, the demand for construction materials like aggregates, limestone, and granite is rising. This trend indirectly boosts the demand for mining explosives as quarrying and aggregate mining require effective blasting for material extraction. The mining explosives market, therefore, remains closely linked with construction, urbanisation, and industrialisation trends.

In addition to mining companies, the market consists of prominent explosive manufacturers, blasting service providers, and technical consultancy firms. Key players are focusing on regional expansion, strategic mergers, and technological collaboration to strengthen their market presence and diversify their product portfolio. Some companies are also investing in green mining initiatives and research to develop eco-friendly explosives with minimal toxic by-products to align with environmental sustainability goals.

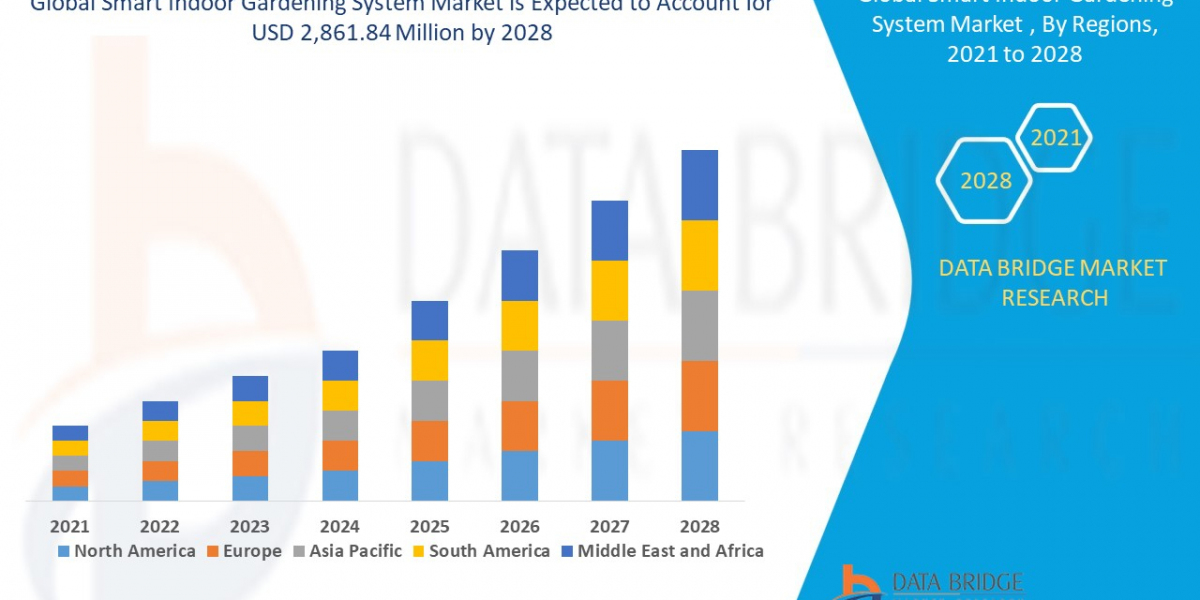

The Asia Pacific region holds the largest share in the mining explosives market, attributed to the high mining output, large reserves, and growing industrial activities in countries like China, India, and Indonesia. Africa is emerging as a potential market due to rich mineral reserves and increased foreign investments in mining infrastructure. North America and Europe also have significant market shares but face stringent environmental regulations, which influence the choice and use of explosives in these regions.

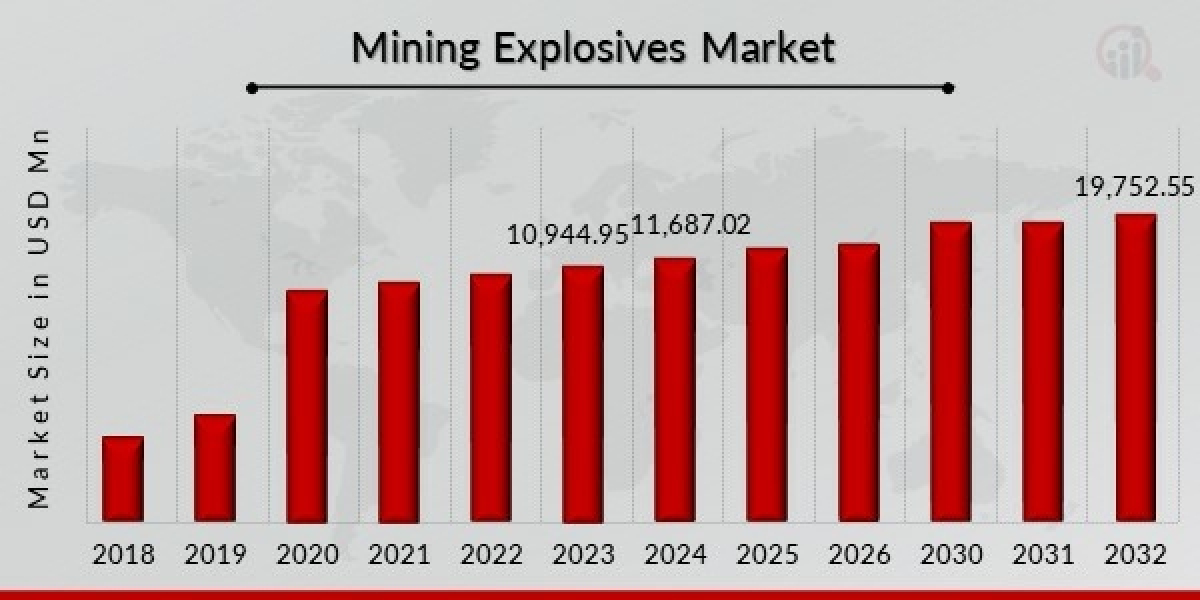

Looking ahead, the mining explosives market is expected to grow steadily with the rising global demand for minerals and metals, technological innovations in blasting practices, and the increasing shift towards underground mining operations. However, the market will also be shaped by regulatory frameworks, environmental considerations, and advancements in alternative excavation technologies like mechanical rock cutting and non-explosive demolition agents, which are emerging to complement traditional blasting methods.