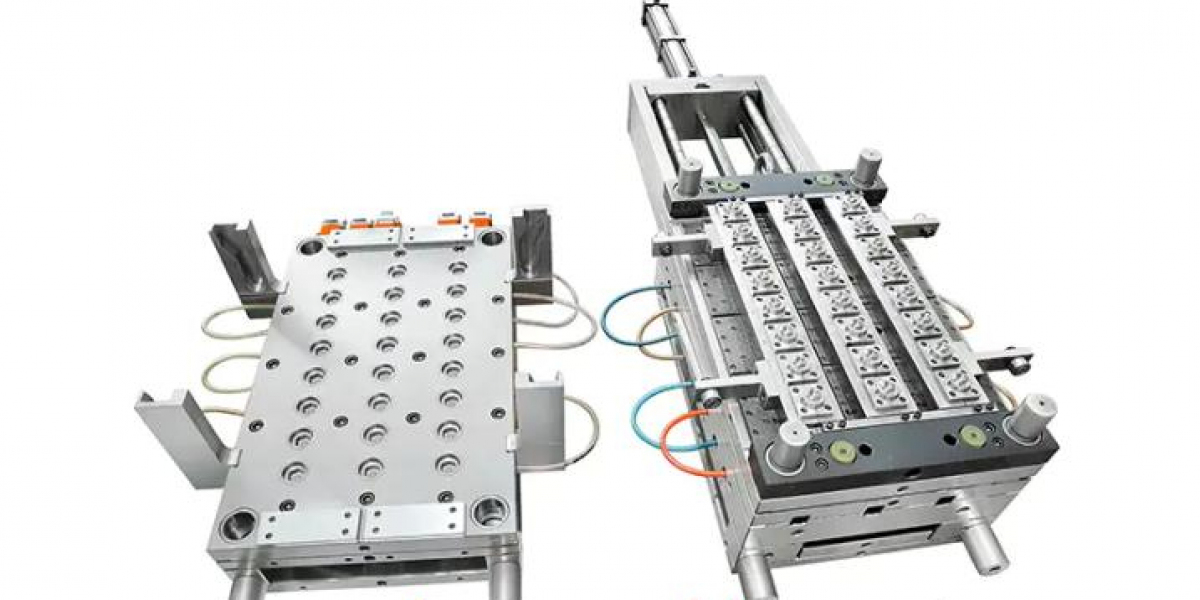

In today's rapidly evolving packaging industry, the Cap Compression Moulding Machine plays a pivotal role in meeting the rising market demand for high-quality plastic caps. Positioned at the heart of bottle cap manufacturing, this machine is essential for producing durable and precisely shaped caps efficiently. The increasing variety of packaging types and consumer expectations has spurred manufacturers like Taizhou Chuangzhen Machinery Manufacturing to push technological upgrades that enhance machine performance and versatility.

One of the most significant factors influencing the market demand for the Cap Compression Moulding Machine is the global surge in bottled products, ranging from beverages to pharmaceuticals and cosmetics. With this expansion, manufacturers are under pressure to produce caps that not only seal containers effectively but also comply with regulatory standards regarding safety and environmental impact. This requires advanced machinery capable of precision molding, quick changeovers, and consistent output quality.

Technological upgrades have been the answer to these demands. Taizhou Chuangzhen Machinery Manufacturing has integrated intelligent control systems into their cap compression moulding machines, allowing operators to monitor and adjust parameters such as temperature, pressure, and cycle time with unprecedented accuracy. This smart technology reduces waste, minimizes defects, and improves overall productivity. Additionally, improvements in automation have facilitated the handling of diverse cap designs without extensive manual intervention, boosting operational efficiency.

Beyond technical enhancements, industry applications for cap compression moulding machines continue to expand. The food and beverage sector remains a primary user, but increasing environmental awareness has accelerated demand in the production of eco-friendly caps made from biodegradable or recycled plastics. This shift challenges manufacturers to develop machines that can process these newer materials reliably while maintaining product integrity. Taizhou Chuangzhen’s machinery meets these challenges with adaptable molds and precision compression techniques that ensure consistent quality even with alternative materials.

Moreover, the pharmaceutical industry demands stringent quality assurance, requiring caps that guarantee product safety and tamper evidence. Cap compression moulding machines used in this sector must comply with exacting standards, producing caps with perfect sealing properties and smooth finishes. Advanced inspection modules integrated into these machines help detect defects immediately, preventing faulty caps from reaching consumers.

The evolving market and technological landscape underline the importance of selecting the right machinery for cap manufacturing. Choosing a high-performance Cap Compression Moulding Machine from a reputable manufacturer like Taizhou Chuangzhen ensures access to cutting-edge features, durable construction, and responsive after-sales service. Such machines are investments in maintaining competitive advantage through innovation and quality assurance.For more detailed information on state-of-the-art cap compression moulding machines and to explore specific models tailored to diverse industry needs, visit Taizhou Chuangzhen Machinery Manufacturing’s official website at https://www.capping-machine.net/ .