The robotics system integration market size has witnessed substantial growth over the past decade, driven by increasing adoption of smart manufacturing technologies. Market size is expanding as businesses invest in robotics to improve efficiency, ensure precision, and minimize human errors. The integration of artificial intelligence and machine learning within these systems has further boosted demand, allowing companies to scale operations with minimal manual intervention.

The Robotics System Integration Market has emerged as a critical segment within the broader robotics and automation industry. As businesses strive to enhance operational efficiency, reduce costs, and improve production quality, the demand for integrated robotics solutions has witnessed significant growth. Robotics system integration involves combining various robotic components such as hardware, software, sensors, and actuators into a unified, functional system capable of performing complex industrial tasks. These integrations enable industries to streamline processes, automate repetitive tasks, and enhance productivity, making them indispensable in modern manufacturing, logistics, and service sectors.

Market Dynamics

The market dynamics of robotics system integration are shaped by multiple factors, including technological advancements, rising labor costs, and the need for operational efficiency. The growing adoption of smart manufacturing practices under Industry 4.0 has fueled demand for robotics solutions that can be seamlessly integrated into existing workflows. Companies are increasingly focusing on system flexibility, modularity, and scalability to meet evolving production requirements. Furthermore, the convergence of robotics with artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) has expanded the scope of system integration, enabling real-time monitoring, predictive maintenance, and adaptive manufacturing.

Drivers of Market Growth

Several factors are driving the expansion of the robotics system integration market. First, the rising labor costs in developed economies have compelled manufacturers to adopt automation to reduce dependency on human labor. Second, the need for high-precision operations, especially in sectors like automotive, electronics, and pharmaceuticals, has increased demand for integrated robotic solutions. Third, growing investments in smart factories and automation infrastructure are pushing companies toward adopting integrated robotic systems. Additionally, the rising awareness of operational safety and workplace ergonomics is driving the deployment of robotic systems that can handle hazardous or physically demanding tasks.

Market Restraints

Despite strong growth, the robotics system integration market faces certain challenges. High initial capital investment and system installation costs can deter small and medium-sized enterprises (SMEs) from adopting integrated robotic solutions. Moreover, the complexity of integrating different robotic systems and components requires skilled engineers and technicians, which may limit market penetration in regions with a shortage of qualified workforce. Additionally, compatibility issues between existing systems and new robotic technologies can pose integration challenges, slowing down adoption rates. Regulatory and compliance requirements in specific industries, particularly healthcare and defense, may also restrict the widespread deployment of robotics integration.

Segmentation of the Market

The robotics system integration market can be segmented based on type, component, end-user industry, and region. By type, the market includes fixed robotic systems, mobile robotic systems, and collaborative robots (cobots). Fixed robotic systems are commonly deployed in manufacturing plants for repetitive tasks, while mobile robots are used in logistics, warehousing, and material handling. Cobots, designed to work safely alongside human operators, are gaining traction in SMEs and service industries.

In terms of components, the market comprises hardware, software, sensors, and controllers. Hardware includes robotic arms, actuators, and end-effectors, while software consists of programming and control platforms that enable system coordination. Sensors play a crucial role in facilitating real-time feedback, precision, and adaptive responses. Controllers manage the overall operation and communication among system components.

By end-user industry, automotive, electronics, healthcare, aerospace, food & beverages, and logistics are the primary sectors leveraging robotics system integration. The automotive industry remains a dominant segment due to its high-volume production requirements and demand for precision. Electronics and semiconductor manufacturing rely heavily on robotic integration to handle delicate components and achieve high throughput. Healthcare applications include surgical robots and automated laboratory systems, while logistics and warehousing utilize autonomous mobile robots for material transport and order fulfillment.

Challenges and Market Constraints

While the robotics system integration market is expanding, it faces several critical challenges. The integration process often involves complex engineering, testing, and calibration, which can extend deployment timelines and increase costs. Furthermore, rapid technological advancements in robotics and AI can render existing systems obsolete, requiring continuous investment in upgrades and training. Cybersecurity risks are another concern, as connected robotic systems may be vulnerable to hacking and data breaches, impacting operational safety and confidentiality. Additionally, the global shortage of skilled robotics engineers limits the ability of companies to implement sophisticated integrations effectively.

Future Outlook

The future of the robotics system integration market is promising, driven by continuous innovation and rising demand for automation across industries. Emerging technologies like AI-driven predictive analytics, collaborative robots, and cloud-based control systems are expected to enhance system intelligence and flexibility. As manufacturing shifts toward smart factories and digitalized production, the adoption of integrated robotics systems will accelerate.

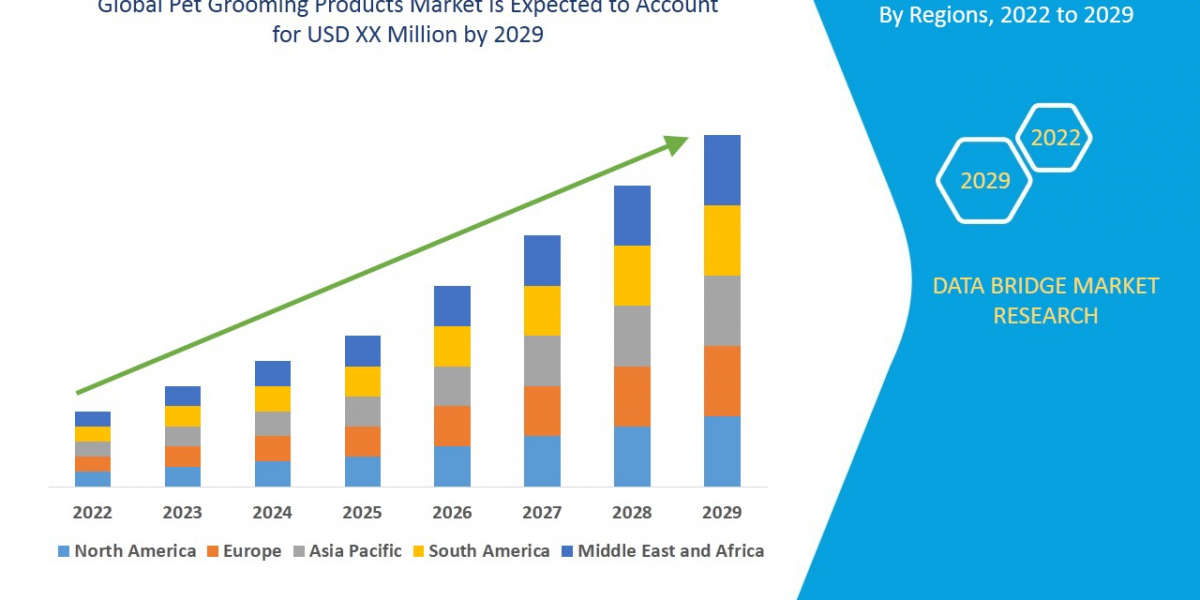

Moreover, the trend of robotics-as-a-service (RaaS) is likely to reduce entry barriers for SMEs by allowing access to advanced robotic solutions without substantial upfront investments. Geographically, North America and Europe are currently leading the market due to well-established industrial infrastructure and high automation adoption. However, Asia-Pacific is projected to witness significant growth, fueled by rapid industrialization, favorable government initiatives, and increasing investment in advanced manufacturing technologies.

Multi-Tasking Machine Tools Market Trends

Vacuum Coating Machines Market Trends