The roller coating machine Market Growth trajectory is fueled by technological advancements and increasing industrial automation. Factors such as enhanced production efficiency, reduced labor costs, and consistent product quality are key drivers. Additionally, the growing focus on environmentally friendly coating solutions and sustainable manufacturing practices further accelerates market growth globally.

The roller coating machine market has witnessed remarkable growth over the past few years due to the increasing demand for efficient, high-quality coating solutions across multiple industries. Roller coating machines are specialized equipment designed to apply a uniform layer of liquid coating, paint, or adhesive onto a substrate using rollers. These machines are widely employed in industries such as automotive, construction, packaging, and furniture manufacturing. Their ability to ensure consistency, reduce waste, and enhance productivity has made them a vital component in modern manufacturing processes. The roller coating machine market is poised for significant growth as manufacturers continue to prioritize quality, efficiency, and cost-effectiveness in their production lines.

Market Overview

The roller coating machine market is characterized by a diverse range of products, including manual, semi-automatic, and fully automated roller coating machines. Manual machines are often utilized by small-scale manufacturers due to their affordability and ease of operation. Semi-automatic machines offer a balance between productivity and cost, while fully automated machines cater to high-volume industrial applications, delivering precision and minimal material wastage. The increasing adoption of automation in industrial processes has boosted the demand for advanced roller coating systems that can operate continuously and provide consistent coating quality. Moreover, the growing awareness of eco-friendly coatings and the need to reduce solvent emissions have encouraged manufacturers to innovate in terms of both machine design and coating materials.

Market Drivers

Several factors are driving the growth of the roller coating machine market. One of the primary drivers is the increasing demand for surface-treated materials across various sectors. For instance, in the automotive industry, coated components offer enhanced durability, resistance to corrosion, and aesthetic appeal, making roller coating machines indispensable in the production process. Similarly, in the packaging industry, coated surfaces provide improved printability and product protection, further boosting the need for efficient coating solutions.

Another significant driver is technological advancements in roller coating equipment. Innovations such as precision roller systems, computer-controlled coating thickness adjustment, and energy-efficient motors have improved the overall performance and reliability of these machines. Manufacturers are also investing in research to develop machines compatible with water-based coatings, which are environmentally friendly and meet stringent regulatory standards. Additionally, the integration of Internet of Things (IoT) technology enables real-time monitoring and predictive maintenance, minimizing downtime and enhancing operational efficiency.

Market Trends

Several notable trends are shaping the roller coating machine market. One major trend is the shift towards automation and smart manufacturing. Industrial operators increasingly prefer automated roller coating machines that reduce manual intervention, improve process accuracy, and enhance production speed. Smart sensors and digital controls allow operators to monitor coating parameters, track material usage, and optimize performance, resulting in significant cost savings and higher product quality.

Another trend is the adoption of eco-friendly coating processes. With growing concerns about environmental impact and regulatory pressures, manufacturers are seeking solutions that minimize solvent emissions, reduce energy consumption, and enable the use of sustainable coating materials. Water-based coatings, UV-curable coatings, and solvent-free options are gaining popularity, driving demand for machines compatible with these advanced materials.

Furthermore, the demand for customized roller coating machines is increasing. Manufacturers are seeking equipment that can handle diverse substrate sizes, coating thicknesses, and material types. This trend is particularly evident in the packaging and furniture industries, where unique product specifications require flexible and adaptable coating solutions.

Regional Insights

Geographically, the roller coating machine market is expanding across multiple regions. Asia-Pacific is emerging as a significant market due to rapid industrialization, growing automotive and packaging sectors, and rising investments in manufacturing infrastructure. Countries such as China, India, and Japan are witnessing increased adoption of advanced coating machinery to meet the quality and production demands of modern industries.

North America and Europe are also important markets, driven by technological innovation and stringent quality standards. Manufacturers in these regions are focusing on energy-efficient and environmentally friendly machines to comply with regulatory norms while enhancing operational efficiency. The presence of established industrial players and continuous R&D initiatives further strengthens the market position in these regions.

Future Outlook and Market Forecast

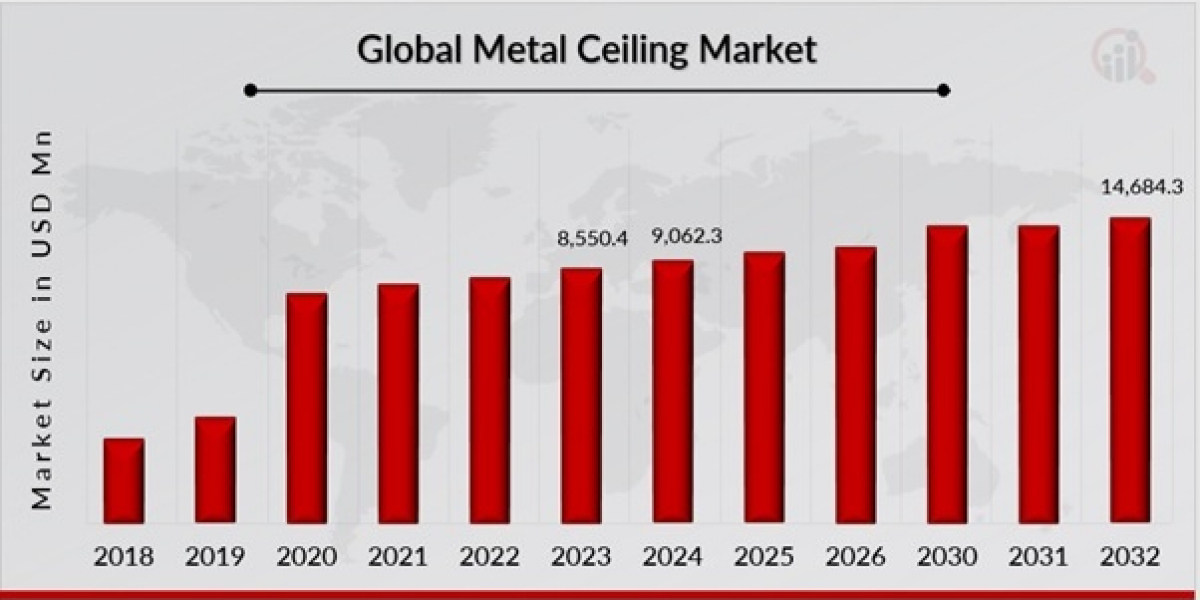

The future of the roller coating machine market looks promising, with steady growth expected in the coming years. Increasing industrial automation, rising demand for high-quality coated products, and advancements in eco-friendly coating technologies will continue to drive market expansion. Companies are likely to focus on developing machines that offer higher precision, faster production speeds, and lower operational costs.

Additionally, collaborations and partnerships between machine manufacturers and coating material suppliers are anticipated to create integrated solutions that enhance process efficiency and performance. The demand for versatile machines capable of handling multiple coating types and substrates will grow, particularly in industries that require high customization.