The Nitinol market has been witnessing steady growth in recent years, driven by rising demand in the medical and industrial sectors. Nitinol, a unique nickel-titanium alloy, is widely recognized for its two remarkable properties: superelasticity and shape memory. These characteristics allow Nitinol to return to its original form after deformation, making it ideal for applications ranging from medical implants to surgical instruments. As healthcare technology advances and minimally invasive procedures become the norm, the demand for Nitinol is expected to grow exponentially.

Understanding Superelastic Alloys

Nitinol belongs to a category of superelastic alloys. Unlike conventional metals, superelastic alloys can endure large mechanical strains and revert to their initial shape without permanent deformation. This property is particularly advantageous in the medical field, where devices need to adapt to the human body's intricate structures. For example, stents and guidewires made from Nitinol can navigate through narrow blood vessels while maintaining their shape, ensuring optimal performance during implantation.

The superelasticity of Nitinol also reduces stress on surrounding tissues during surgical procedures. This characteristic not only enhances device performance but also minimizes patient discomfort and post-operative complications, making Nitinol a preferred choice in medical technology.

Nitinol in Medical Implants

The healthcare industry has been one of the largest adopters of Nitinol. Its combination of superelasticity, shape memory, and biocompatibility makes it ideal for a variety of medical implants. For instance, self-expanding stents, used in cardiovascular surgeries, rely on Nitinol's ability to expand at body temperature and conform to the vessel walls. Similarly, orthopedic staples, bone screws, and spinal implants utilize Nitinol to provide precise alignment and stable fixation.

Orthodontic archwires are another notable example of Nitinol in medical implants. Nitinol's shape memory properties allow these wires to apply consistent pressure over time, gradually realigning teeth while reducing discomfort compared to traditional metal wires. As dental and cardiovascular procedures continue to advance, the demand for Nitinol-based implants is expected to increase significantly.

Enhancing Surgical Instruments with Nitinol

Surgical instruments are another area where Nitinol's superelastic alloys properties are highly beneficial. Instruments such as forceps, scissors, and clamps are often required to perform precise tasks in confined spaces. Nitinol provides the flexibility and durability necessary to maintain instrument performance without permanent deformation.

For example, minimally invasive surgical procedures demand tools that can navigate complex anatomy without compromising structural integrity. Instruments made from Nitinol allow surgeons to achieve high precision, reducing tissue damage and improving patient outcomes. The demand for such advanced instruments is growing alongside the trend toward minimally invasive surgeries globally.

Nitinol Suppliers: Meeting Rising Demand

The global Nitinol suppliers network has expanded to meet the increasing demand for this specialized alloy. Companies across the U.S., Europe, and Asia are now providing high-quality Nitinol in forms such as wires, rods, sheets, and tubes. Indian suppliers, such as Jaydeep Steels and Special Metal, have become major players, catering to both domestic and international markets.

These suppliers offer a wide range of Nitinol grades to accommodate specific applications in medical devices, robotics, and industrial equipment. By providing customized solutions and consistent material quality, Nitinol suppliers are playing a pivotal role in enabling market growth and technological innovation.

Nitinol Wire Price: Market Considerations

The nitinol wire price is influenced by multiple factors including material composition, diameter, supplier, and order quantity. On average, Nitinol wire prices range from $0.75 to $30 per kilogram. Premium grades with higher nickel content or specialized properties command higher prices due to enhanced performance characteristics.

For medical applications, quality and reliability often outweigh cost considerations. Manufacturers prioritize certified suppliers and consistent material specifications to ensure safety and efficacy in critical medical applications such as medical implants and surgical devices.

Shape Memory Alloy: A Game-Changer

Nitinol is a prominent shape memory alloy (SMA), a class of materials that “remember” their original shape and return to it when exposed to specific stimuli, such as heat. This property is especially useful in medical applications where devices need to expand or contract once inside the human body.

Shape memory alloys enable innovations such as self-expanding stents, orthodontic wires, and catheter guidewires. These devices not only simplify surgical procedures but also improve recovery times for patients. Beyond healthcare, SMAs are being explored in robotics, aerospace, and consumer electronics, underscoring Nitinol’s versatility.

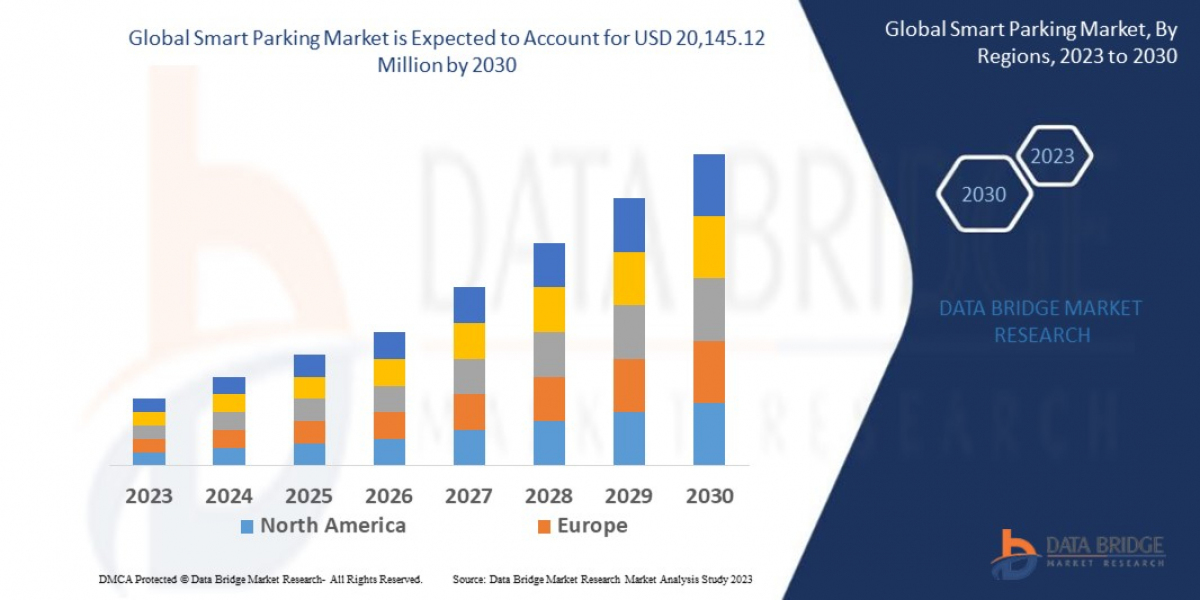

Market Trends and Future Prospects

The Nitinol market is expected to grow at a robust rate in the coming years due to several factors:

- Rising prevalence of cardiovascular diseases: Increasing demand for stents and vascular implants.

- Advancements in minimally invasive surgery: Driving the use of superelastic instruments.

- Growth in dental and orthopedic applications: Expanding the use of shape memory alloys.

- Global supplier expansion: Facilitating easier access to high-quality Nitinol materials.

Technological innovations, combined with a growing focus on patient safety and precision, are creating new opportunities for Nitinol in healthcare and beyond.

Conclusion

The Nitinol market represents a unique intersection of material science and medical innovation. With its unmatched superelastic alloys properties, applications in medical implants and surgical instruments, and the support of reliable nitinol suppliers, this material is transforming modern healthcare. Coupled with the versatility of shape memory alloy technology and evolving market trends, Nitinol is poised to play a critical role in the next generation of medical devices and industrial applications. As the market continues to expand, both suppliers and end-users are expected to benefit from its remarkable capabilities and wide-ranging potential.