Global Semiconductor Manufacturing Equipment Market

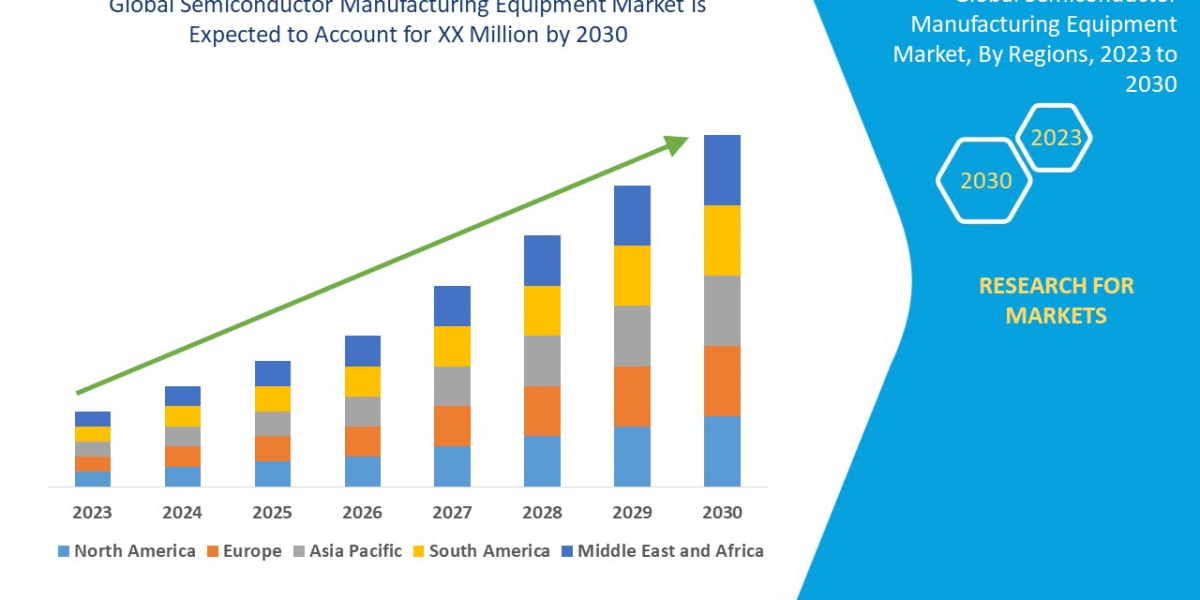

Data Bridge Market Research analyses that global semiconductor manufacturing equipment market will grow at a CAGR of 9.5% during the forecast period of 2023 to 2030.

The global semiconductor manufacturing equipment market plays a vital role in the advancement of modern technology, powering everything from smartphones and computers to automobiles, medical devices, and industrial systems. As digital transformation accelerates across industries, demand for high-performance semiconductors has surged, driving continuous innovation in manufacturing processes and equipment. This market has become a cornerstone of the global technology ecosystem, enabling the miniaturization, speed, and efficiency that define today’s electronics.

Market Overview

The semiconductor manufacturing equipment market encompasses tools, machines, and systems used to produce semiconductor devices. These include wafer processing equipment, assembly and packaging equipment, and testing machinery. The market is primarily driven by the increasing demand for advanced chips that support technologies such as artificial intelligence (AI), Internet of Things (IoT), 5G, autonomous vehicles, and cloud computing.

https://www.databridgemarketresearch.com/reports/global-semiconductor-manufacturing-equipment-market

In recent years, the expansion of foundries, rising investments in semiconductor fabrication plants (fabs), and the strategic push by various nations to strengthen chip manufacturing capabilities have significantly contributed to the market’s growth. The semiconductor industry is cyclical in nature, but the long-term outlook remains robust as the demand for chips continues to rise across multiple end-user sectors.

Market Dynamics

Drivers

Growing Demand for Advanced Electronics

With the proliferation of smart devices, wearables, and connected systems, the need for advanced semiconductor chips has increased exponentially. These chips require sophisticated equipment for their production, especially with the shift toward smaller process nodes and 3D architectures.

Rise of AI and 5G Technologies

Artificial intelligence and 5G networks demand semiconductors with higher processing power, lower latency, and greater energy efficiency. To meet these requirements, manufacturers are investing heavily in next-generation lithography and wafer fabrication tools, boosting the demand for semiconductor manufacturing equipment.

Government Initiatives and Incentives

Governments worldwide, particularly in the U.S., China, South Korea, Japan, and the European Union, are implementing policies and funding programs to promote domestic semiconductor production. Initiatives such as the U.S. CHIPS Act and similar programs in Asia and Europe are encouraging the establishment of new fabs and expansion of existing ones, creating a surge in demand for manufacturing equipment.

Expansion of Foundries and IDMs

The growth of leading foundries like TSMC, Samsung, and Intel has accelerated investments in advanced manufacturing facilities. Integrated Device Manufacturers (IDMs) are also modernizing their production lines to remain competitive, fueling equipment sales across various categories.

Restraints

High Capital Requirements

Setting up and maintaining semiconductor fabs involves enormous capital expenditure. Advanced equipment, particularly for processes below 5 nanometers, comes with significant costs that only a few companies can afford, limiting market entry.

Technological Complexity

As semiconductor processes become increasingly sophisticated, the equipment needed to produce them becomes more complex and expensive. This poses challenges for smaller equipment manufacturers and can lead to supply bottlenecks.

Geopolitical Tensions and Supply Chain Disruptions

Trade restrictions, export controls, and geopolitical conflicts have disrupted the global semiconductor supply chain. Tensions between major economies such as the U.S. and China have led to regulatory challenges that impact equipment suppliers and buyers alike.

Market Segmentation

The semiconductor manufacturing equipment market is segmented based on equipment type, product type, fabrication process, and region.

By Equipment Type

Front-End Equipment: Includes lithography, etching, deposition, and cleaning systems used in wafer processing.

Back-End Equipment: Covers assembly, packaging, and testing tools.

Others: Include automation and inspection equipment.

By Product Type

Memory: DRAM, NAND, and other memory chips that require specialized fabrication tools.

Logic: Processors and controllers for computing and AI applications.

Analog and Mixed Signal: Used in sensors and power management devices.

By Fabrication Process

Wafer Processing: Dominates the market due to the increasing demand for advanced wafer technologies.

Assembly and Packaging: Growing as miniaturization and chip integration trends intensify.

Testing: Essential to ensure reliability and performance, especially in automotive and aerospace electronics.

Regional Analysis

Asia-Pacific

Asia-Pacific leads the global semiconductor manufacturing equipment market, accounting for the majority of global revenue. Countries such as Taiwan, South Korea, Japan, and China are at the forefront due to their well-established semiconductor ecosystems. Taiwan is home to TSMC, the world’s largest foundry, while South Korea’s Samsung and SK Hynix dominate memory production. China is also investing heavily to build domestic capabilities, despite trade restrictions and export control challenges.

North America

North America, led by the United States, holds a significant share of the market. The U.S. is investing billions through the CHIPS and Science Act to encourage domestic semiconductor manufacturing. Key equipment manufacturers such as Applied Materials, Lam Research, and KLA Corporation are headquartered in the U.S., contributing to its strong position in the global market.

Europe

Europe’s semiconductor equipment market is gaining momentum, supported by EU initiatives aimed at enhancing technological sovereignty. Countries like Germany and the Netherlands are key players, with ASML leading the global market in lithography equipment. The focus on automotive semiconductors and industrial automation has further strengthened Europe’s presence in the industry.

Rest of the World

Regions such as the Middle East and Latin America are gradually exploring opportunities in the semiconductor value chain, primarily through partnerships and technology imports. However, their participation remains limited compared to Asia and North America.

Competitive Landscape

The global semiconductor manufacturing equipment market is dominated by a few key players that drive technological innovation and maintain a competitive edge through research and development. Major companies include:

ASML Holding N.V. – The global leader in photolithography equipment, known for its EUV (Extreme Ultraviolet) lithography systems essential for advanced chip production.

Applied Materials Inc. – Specializes in materials engineering solutions used in wafer fabrication.

Lam Research Corporation – Renowned for its etching and deposition equipment.

Tokyo Electron Limited – A key Japanese manufacturer providing a range of semiconductor production tools.

KLA Corporation – Focused on inspection and metrology systems that ensure chip quality and precision.

These companies continue to expand their portfolios through technological innovation, mergers, partnerships, and global expansion strategies.

Future Outlook

The future of the semiconductor manufacturing equipment market looks promising, with substantial opportunities emerging from ongoing digitalization, the evolution of AI, and the growth of electric vehicles. Equipment manufacturers are investing in advanced process technologies, such as EUV lithography, atomic layer deposition, and chemical vapor deposition, to meet the demands of next-generation chips.

Furthermore, the shift toward sustainability and green manufacturing is expected to influence equipment design and operation. Energy-efficient tools, reduced chemical usage, and recycling processes will become key differentiators in the coming years.

Conclusion

The global semiconductor manufacturing equipment market stands as a critical pillar of technological progress, supporting industries that define the modern digital age. Despite challenges like high capital costs and supply chain constraints, the market’s growth trajectory remains strong. Driven by innovations in AI, 5G, and advanced computing, along with strategic government initiatives worldwide, the semiconductor equipment sector is poised for sustained expansion. As the world’s reliance on semiconductors deepens, the demand for efficient, precise, and innovative manufacturing equipment will continue to shape the future of global technology.

Global Fitness Equipment Market

Global Mobile Games Market

Global Risk Management Software Market

Global Thermal Paper Market

Global Antihypertensives Market

Global Digital Health Technologies Market

Global Keloid Treatment Market

Global Propane Market

Global Prescription Digital Therapeutics (PDTx) Market

Global Ultralight and Light Aircraft Market

Asia-Pacific Fitness Equipment Market

Europe Fitness Equipment Market

North America Fitness Equipment Market

North America In-Flight Catering Services Market

LATAM Intermediate Bulk Containers (IBC) Market